What does an excavator look like

7 Types of Excavators and Their Uses on the Construction Site

An excavator is a must on your job site when you need to lift heavy amounts of soil. Excavators are popular earthmoving vehicles that feature a bucket, arm, rotating cab and movable tracks. These components provide superior digging power and mobility, allowing this heavy equipment to perform a variety of functions, from digging trenches and breaking holes to lifting away waste and excavating mines.

- Crawler Excavators

- Wheeled Excavators

- Dragline Excavators

- Suction Excavators

- Skid Steer Excavators

- Long Reach Excavators

- Mini Excavators

What are excavators used for? Excavators are applied to a variety of contractor and industrial needs, including mining, road construction, building construction and demolitions.

There are many types of excavators — smaller machines handle digging and drilling functions, while larger excavators have different tools for heavy-duty projects. When renting your excavator, you’ll want to consider its size and speed as well as working conditions on the job site, such as the amount of space and the soil types.

The most common excavator types are crawler, dragline, suction, skid steer and long reach excavators. We’ll go over each type of excavator and the work each one is best used for.

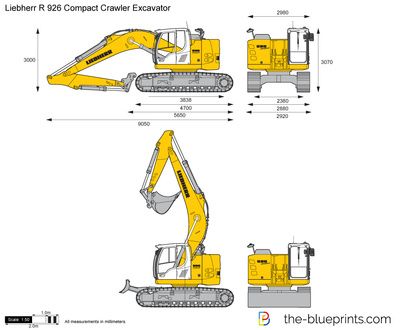

1. Crawler ExcavatorsUnlike other large excavators that run on wheels, crawlers run on two large endless tracks and are optimal for mining and heavy-duty construction jobs. Also known as compact excavators, these excavators use hydraulic power mechanisms to lift heavy debris and soil.

Their chain wheel system allows them to slide down and scale hills with less risk, making them suitable for grading hilly areas and landscaping uneven terrain. While slower than other excavators, crawlers provide greater balance, flexibility and stability overall.

Pros: Provide greater balance and stability on uneven ground

Cons: Slower than some other excavators

2. Wheeled Excavators

Wheeled Excavators

Wheeled excavators are similar in size and appearance to crawlers but run on wheels instead of tracks. Replacing tracks with wheels makes them faster and easier to maneuver on concrete, asphalt and other flat surfaces while still offering the same power capabilities.

Because wheels offer less stability on uneven ground than tracks, wheeled excavators are commonly used for roadwork and urban projects. However, operators can add outriggers to increase stability when transitioning between asphalt or concrete and an uneven surface.

Pros: Fast and easy to maneuver on flat surfaces

Cons: Perform poorly on uneven terrain

3. Dragline ExcavatorsThe dragline excavator is a larger excavator that operates with a different process. The equipment utilizes a hoist rope system that attaches to a bucket via a hoist coupler. The other side of the bucket is affixed to a dragline that runs from the bucket to the cab. The hoist rope raises and lowers the bucket while the dragline pulls the bucket toward the driver.

The hoist rope raises and lowers the bucket while the dragline pulls the bucket toward the driver.

Due to their weight, draglines are often assembled on-site. The unique system of this type of excavator is commonly used in large-scale civil engineering projects like canal dreading.

Pros: Dragline system is ideal for underwater excavating and canal dreading

Cons: Weight and size make it impractical for smaller jobs

4. Suction ExcavatorsAlso known as vacuum excavators, suction excavators feature a suction pipe capable of providing up to 400 horsepower. The excavator first releases a water jet to loosen the ground.

The pipe, which contains sharp teeth at the edge, then creates a vacuum that carries away soil and debris up to 200 miles per hour.

A suction excavator is ideal for delicate underground applications, as it can reduce the chance of damage by more than 50 percent.

Pros: Added precision reduces damage during delicate jobs

Cons: Narrow suction pipes are impractical for large-scale applications

5. Skid Steer Excavators

Skid Steer ExcavatorsUnlike standard excavators, skid steers have booms and buckets that face away from the driver. This orientation allows the attachments to reach over the cab instead of around it, making these excavators useful in more narrow areas and maneuvering tricky turns.

They are often used for digging pools, site cleaning, residential work and debris removal, where space is more limited and objects are spread far apart.

Pros: Easy to maneuver in tight and narrow spaces

Cons: Don’t perform as well on uneven or slippery surfaces

6. Long Reach ExcavatorsAs its name suggests, a long reach excavator features a lengthier arm and boom sections. The design allows for better operation in hard-to-reach locations. The excavator’s extendable arm can reach over 100 feet horizontally.

These excavators are best used for demolition projects like structural crumbling and breaking down walls over bodies of water. Different attachments can be affixed to the arm to perform additional jobs such as shearing, crushing and cutting.

Different attachments can be affixed to the arm to perform additional jobs such as shearing, crushing and cutting.

Pros: Longer boom is ideal for hard-to-reach locations and demolition projects

Cons: Difficult to use in tight spaces

7. Mini ExcavatorsIn recent years, more contractors are using mini excavators, a smaller and lighter version of the standard excavator capable of minimizing ground damage and fitting through crowded, narrow sites like parking lots and indoor spaces. Also known as compact excavators, mini excavators typically incorporate reduced tail-swing or zero tail-swing to maneuver tighter turns and avoid contact with any obstacles.

Pros: Easily fits into tight spaces and can be used indoors

Cons: Can only handle smaller loads

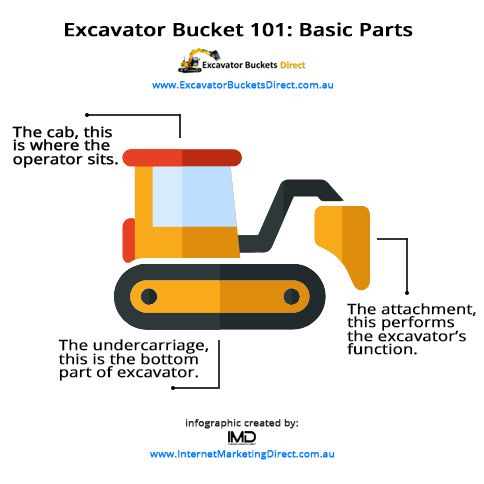

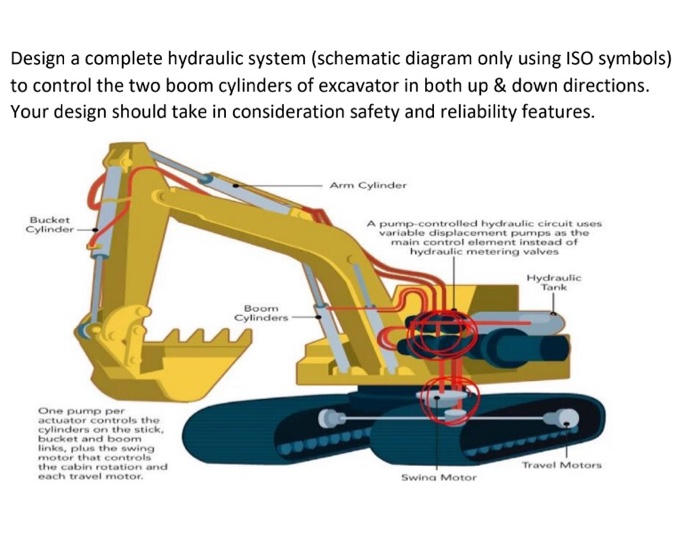

Excavator Attachments and PartsAn excavator’s design allows it to serve many versatile purposes. Hydraulic cylinders, booms, arms and attachments provide digging and holding functionalities, while a house-like cab provides the driver with controls to direct the excavator. A rotating platform and wheels provide the necessary mobility to lift and remove debris from the worksite.

Hydraulic cylinders, booms, arms and attachments provide digging and holding functionalities, while a house-like cab provides the driver with controls to direct the excavator. A rotating platform and wheels provide the necessary mobility to lift and remove debris from the worksite.

Excavators use a variety of hydraulic attachments that serve different purposes. In addition to a bucket, other common attachments include an auger, breaker, clamp and quick coupler.

Bucket

Buckets are the most common attachments seen on excavators. These steel attachments have teeth-like edges that can provide digging and scooping capabilities. Buckets come in different varieties, the most common being ditching buckets designed for grading stones and trenching buckets used to dig trenches.

Auger

Attaching an auger allows you to bore into the ground. Powered by hydraulic circuits, these helical attachments can reach over objects and drill deep holes. Augers come in different specifications and sizes for various digging conditions and terrains — they range from 4 inches to 50 inches in length and can dig up to 32 feet.

Breaker

Breakers are similar to jackhammers but are much larger in size. With the ability to provide up to 1,000 pounds of impact energy, these attachments can break into tougher surfaces like stone and concrete.

Clamp

Clamps allow excavator operators to pick up large materials that are too oversized for a bucket, such as tree stumps and concrete. The attachments can be used with buckets or as pieces in a grapple. Clamps are easy to attach and detach from excavators.

Coupler

Couplers allow you to quickly switch between tools and attachments without a crew. Their versatility is handy when moving between different tasks and processes on a job site.

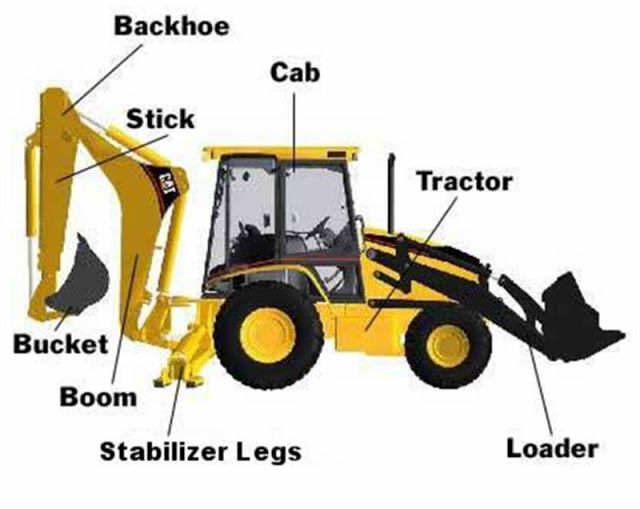

Differences Between an Excavator and a DiggerBackhoes, also known as diggers, are a common fixture on construction sites but are often confused with excavators. While they share similar digging and lifting capabilities, backhoes and excavators differ in size, weight and functionality.

Excavators are generally large equipment weighing up to 200,000 pounds. Their bucket and boom design allow them to rotate a full 360 degrees.

A backhoe, on the other hand, is generally much smaller and shares more similarities in appearance with a tractor. The design means a backhoe can only rotate 200 degrees from side to side. Its front and back buckets can excavate materials, load waste and drag debris toward the vehicle. Renting a backhoe is best for light or medium-duty jobs with versatile applications.

While there are many different types of excavators, their core functionalities are similar. The lifting and digging abilities make them a staple on just about any construction site. Their high cost makes renting the most cost-effective option for most companies.

Related Posts

The Excavator Explained - Everything about Excavators

This article was last updated on October 31, 2022

Excavators are an essential piece of heavy equipment for most construction projects. Often referred to as diggers, excavators are used for all kinds of jobs like material handling, landscaping, demolition, mining projects, trenching, river dredging, and construction.

Often referred to as diggers, excavators are used for all kinds of jobs like material handling, landscaping, demolition, mining projects, trenching, river dredging, and construction.

The chassis of an excavator is made up of a boom, dipper, and bucket. These pieces connect to a cab that sits on a rotating house. Most excavator cabs can rotate a full 360 degrees for increased visibility. Excavators are available with either tracks or wheels depending on the manufacturer and the nature of the project.

Excavators are available in a variety of sizes and classes and can weigh up to 180,000 lbs. There are many other attachments for excavators that can take the place of the digging bucket to diversify the machine. By swapping out the bucket for an auger, drill, ripper, or rake, excavators can be used for many different jobs.

Choosing the Right Excavator for The JobThe best way to choose what excavator rental is needed for your project is to assess what exactly you need the machine to do. Identifying the right size of excavator, what attachments are needed, and how long you need the equipment will inform your decision to rent an excavator or buy one. It can be more efficient for a job to rent the right size of equipment for what is needed instead of trying to make one piece fit for a variety of jobs.

Identifying the right size of excavator, what attachments are needed, and how long you need the equipment will inform your decision to rent an excavator or buy one. It can be more efficient for a job to rent the right size of equipment for what is needed instead of trying to make one piece fit for a variety of jobs.

Excavators are often used for earthmoving projects or projects where lots of digging is required. That being said, the variety of attachments and excavator rental sizes available make these excavation machines useful in excavation projects of all sizes.

Typically, excavator sizes and classes are broken down into the following categories: mini, medium, large, demolition, long-reach, and wheeled. There are also specialty excavators made specifically for mining. Which size of digger you choose to buy or rent is often determined by the excavator's operating weight.

From a landscaping project to the construction of a completely new high-rise skyscraper, you can expect to see an excavator on almost any construction project, especially in the early stages. The variation in size allows them to be used in big construction projects and small backyard renovations. In addition to the different sizes of excavators, there are also several different types of excavators.

The variation in size allows them to be used in big construction projects and small backyard renovations. In addition to the different sizes of excavators, there are also several different types of excavators.

The Cable vs. Hydraulic Excavator

The difference between the cable and hydraulic excavator comes from how the parts of the machine move. Cable excavators use a series of steel wires and cables to move the main parts and replaced steam shovels in the early 1900s.

Hydraulic excavators work by allowing the operator to use levers to control the movement of the hydraulic system to push and move the cylinders that control the boom and bucket of an excavator.

Find the average excavator rental rates in your area

The 6 Kinds of ExcavatorsThere are seven key types of excavators available on the market: Crawler Excavators, Dragline Excavators, Suction Excavators, Long-Reach Excavators, Mini Excavators, and Wheeled Excavators.

1. Crawler Excavators:

The most commonly recognized excavator used for mining, trench digging, and landscape grading is the crawler excavator. Crawler excavators get their name because of the way they travel on a job site with their tracks. They are incredibly powerful machines with hydraulic power. Because of the tracks, they are better suited for rough and uneven terrain.

2. Dragline Excavators:

Dragline excavators are a larger kind of excavator that uses a hoist rope and dragline system to clear dirt and soil for underwater projects, pile driving, or road excavations. Because of their weight and awkward shape, they're normally hauled in separate pieces to a job site before being assembled. These excavators are used for larger job sites and projects.

3. Suction Excavators:

Suction excavators use water jets and a high-pressure vacuum to clear dirt, soil, and debris. Operated out of a wheeled vehicle, the suction excavator is used for underground applications, debris cleanup, and other delicate excavation projects.

4. Long-Reach Excavators:

With arms that extend up to 100 feet with attachments, the excavator is good for heavy-duty digging, industrial demo projects, and reaching further than most other excavators.

5. Mini Excavator:

A compact, smaller version of a crawler excavator, mini excavators are useful in narrow job sites, job sites with obstacles, and jobs with delicate terrain like landscaping. Mini excavators have zero tail-wing capability and are ideal for small jobs. Mini excavators are also popular for home and DIY landscape projects.

When picking between renting an excavator vs a mini excavator, the size of the project and load size are usually the most important factors.

6. Wheeled Excavator:

The wheeled excavator is the same as a regular excavator but is fitted on wheels instead of tracks. Wheeled excavators are more popular in Europe and are typically used for working in urban areas since their wheels are kinder to finished roads and pavement than the traditional metal track. However, wheeled excavators are becoming more popular for their use in city projects.

However, wheeled excavators are becoming more popular for their use in city projects.

Read more about the differences between tracked and wheeled excavators.

Popular Attachments for ExcavatorsThere are many different mini excavator attachments out there. Renting a specialized attachment can make your machine function more efficiently and work smoother for specific jobs. While there are 10 more popular types of excavator attachments - both for mini excavators and standard machines - you can pretty much rent the attachment that works best for the job you're doing.

The traditional excavator is fitted with a bucket that digs toward the cab and machine. However, this type of digging arm can have a thumb attachment instead which makes it easier to lift and move materials. There are also several types of buckets that can be attached to an excavator.

A rock bucket and a V bucket are two bucket types that can be attached to an excavator. A rock bucket looks similar to a digging bucket but with longer sharper teeth and a narrow V-shaped edge for cutting. The reinforced structural parts of a rock bucket give it the ability to break through hard rock while still maintaining structural integrity. The V bucket simplifies the task of digging trenches and is useful for laying utility cables and pipes.

A rock bucket looks similar to a digging bucket but with longer sharper teeth and a narrow V-shaped edge for cutting. The reinforced structural parts of a rock bucket give it the ability to break through hard rock while still maintaining structural integrity. The V bucket simplifies the task of digging trenches and is useful for laying utility cables and pipes.

Excavators can also be fitted with an auger attachment for digging holes, hammers for breaking up hard concrete and rock, rippers, compactors, rakes, and many other different kinds of tools. All of these attachments help to make the excavator a true multipurpose equipment type.

Manufacturers of ExcavatorsThere are many different manufacturers to consider when looking to buy or rent an excavator. Most companies make different sizes and models of excavators to accommodate projects of all sizes and natures.

A variety of excavators are available for rent through DOZR. There are options to search for excavators ranging from 18 tons to 80 tons as well as high-reach excavators, long-reach excavators, and wheeled excavators for rent. The following is a look at some more popular brands of excavator manufacturers.

The following is a look at some more popular brands of excavator manufacturers.

Caterpillar – also called CAT – was founded in 1925 when C. L. Best Tractor Company joined with Holt Manufacturing Company – the same Holt family responsible for the continual-track system. Caterpillar is one of the most recognized brands of heavy equipment and machinery and is one of the largest heavy equipment manufacturing companies in the world. Caterpillar introduced a series of excavators – called the 200 series – in 1972.

Now, caterpillar excavators feature fuel-efficient engines and the latest safety tech and are designed with productivity in mind. CAT excavators are some of the best-performing earthmoving machines on the market, making them very popular equipment rentals. Their largest excavator is the 395 - Tier 4 model weighing in at 207,300 lbs, just over 100 tons, with a dig depth of 32 feet.

VolvoIt was 1832 in Eskilstuna, Sweden when 27-year-old Johan Theofron Munktell prepared the foundations for the company Volvo Construction Equipment. Today, Volvo excavators continue to push the boundaries of earthmoving and digging equipment. In 2019, Volvo CE announced the goal of launching a range of electric compact excavators and wheel loaders by mid-2020.

Today, Volvo excavators continue to push the boundaries of earthmoving and digging equipment. In 2019, Volvo CE announced the goal of launching a range of electric compact excavators and wheel loaders by mid-2020.

Volvo's line of excavators includes larger crawler excavators, medium crawler excavators, medium-wheeled excavators, and compact, or short-swing, excavators. Volvo is most well-known for its wheeled excavators. Volvo's largest excavator is the EC950F weighing in close to 210,000 lbs or 105 tons with a maximum dig depth of just under 30 feet.

KomatsuKomatsu was established in 1917 in Japan and established in North America later on in 1970. Their introduction to the American market for hydraulic excavators happened with their H-Series in the 1960s, a little before they truly established themselves in America.

Manufacturing all sizes of excavation machinery, Komatsu excavators are for all kinds of projects. With mid-size excavators, large excavators, and surface mining excavators, you're sure to find a Komatsu excavator that will be right for the job. The largest Komatsu excavator is the PC1250LC-11 with an operating weight of 270,000 lbs, a reach of up to 56 feet, and a dig depth of 38 feet.

The largest Komatsu excavator is the PC1250LC-11 with an operating weight of 270,000 lbs, a reach of up to 56 feet, and a dig depth of 38 feet.

John Deere established his company – named after himself – in 1837. In 1969 the first John Deere excavator, the JD690, was introduced. Now, they make over 20 different kinds of excavators ranging in size, weight, and horsepower.

John Deere's largest excavator, the 870 P-Tier, allows for almost 37 feet of dig depth and weighs over 188,000 lbs. John Deere also manufactures compact excavators, another name for mini-excavators, mid-size excavators, and other large excavators.

HitachiEstablished in the early 1900s in Japan, Hitachi didn't start manufacturing construction equipment until the 1950s. Since then, Hitachi has become an innovator in heavy machinery and their excavators are no exception. Currently, Hitachi has 37 excavators on the market.

Hitachi excavators include all sizes of excavators ranging from their smallest non-mini excavator model, the ZX160LC-6, to their biggest excavator, the ZX890LC-6. These models have operating weights and dig depths of 39,000 lbs and 21 feet, and 186,511 lbs and 31 feet, respectively. Hitachi also manufactures mining excavators and mini excavators.

These models have operating weights and dig depths of 39,000 lbs and 21 feet, and 186,511 lbs and 31 feet, respectively. Hitachi also manufactures mining excavators and mini excavators.

Hyundai

Founded in South Korea in 1985, Hyundai built their first excavators in 1988, a 21-ton excavator and a 29-ton excavator. Now, the portfolio of Hyundai excavators includes 16 current models and 28 previous models. The smallest Hyundai excavator model currently, outside of their compact excavators, is the HX130A LCR with an operating weight of just under 15 tons. Their largest excavator is the HX900L with an operating weight of 103 tons.

Doosan

Creating its construction division in 1977, Doosan has been producing excavators since 1978. However, it wasn't until 1994 that Doosan excavators came to America. Doosan currently manufactures crawler excavators, wheeled excavators, and mini excavators. Between the crawler excavators and wheeled excavators, they have 18 products.

The smallest crawler Doosan makes is the DX140LC-7 with an operating weight of 16 tonnes (32,187 lbs) and a dig depth of just over 19 feet. The biggest Doosan excavator is the DX800LC-7 with an operating weight of 90 tonnes and a dig depth of over 27 feet.

Potential Hazards & Safety Protocols for Excavators

Operating any kind of heavy equipment could pose a safety hazard. It is important to always be careful and to only operate heavy equipment and digging machinery like excavators after receiving proper training. Being consistent and following safety protocols can help keep all excavation operations safe. Here are some ways to stay safe while operating an excavator:

-

Never dig under structures like sidewalks without proper support systems

-

Wear a hardhat, safety vest, ear protection, and protection

-

Never dig underneath an excavator

-

Maintain the cab by cleaning up garbage and maintaining clear windows

-

Avoid making sharp turns or sudden movements while operating an excavator

-

Always lower the bucket when parked and park on a level surface

-

Do not travel diagonally on slopes but directly up

-

Map out an excavator route that is as flat as possible

-

Never exceed the maximum weight capacity of an equipment piece

-

Lower the bucket closer to the ground when driving for visibility purposes

-

Check all blind spots before moving equipment

-

Make sure to report any safety hazards and have any needed repairs performed immediately

-

Always wear a seatbelt

-

Check site plans and call local utility companies before beginning to dig

The most important point to remember for any operation of heavy equipment is to only do so if training has been provided and it is safe to do so. There are also some tips and tricks online for special projects like operating an excavator on a slope. Always request training before agreeing to operate a piece of new machinery.

There are also some tips and tricks online for special projects like operating an excavator on a slope. Always request training before agreeing to operate a piece of new machinery.

The first machine to resemble an excavator was the steam shovel. An ancient dinosaur next to the modern excavator, this piece of equipment was a game-changer when it was invented by William Otis who in 1839 received a patent for the design. It was originally fitted on railway tracks to allow mobility.

The machine could move up to 300 cubic yards a day compared to the 12 cubic yards that could be moved by a man. This machine was used to build the Panama Canal and dig the foundations of early skyscrapers. The machine was used and updated into the 1920s as tracked and wheeled equipment became more popular. In 1931 the last railroad shovel was shipped.

Much like with the bulldozer and other pieces of equipment, various pieces had to come together to create the excavator. Sir W.G. Armstrong & Co. was a British business that had developed the hydraulic system that would be used in the modern excavator.

Sir W.G. Armstrong & Co. was a British business that had developed the hydraulic system that would be used in the modern excavator.

Designed to use water instead of hydraulic fluid, this system was invented in 1882. The first hydraulic shovel was patented by Kilgore Machine Co in Minnesota in 1897 and used the technology developed by Sir W.G. Armstrong & Co.

None of these excavators could rotate the full 360 degrees that exist now with the modern excavator. This didn’t happen until the 1960s when a French company called Poclain invented an excavator with cylinders and a hydraulic pump. The TY45 made history as the first fully revolving hydraulic excavator.

The Excavator: FAQCan excavators be used for land clearing?

Excavators are one of the best land-clearing equipment rental options. They're great for clearing trees and moving heavy loads and their tracks make them great for uneven terrain. If you're looking to rent land-clearing equipment, excavators are a great choice.

What is the difference between an excavator vs a backhoe?

Excavators are larger machines that are used primarily for heavy-duty jobs like trenching, demolition, mining, and land clearing because they have longer arms and can dig deeper than a backhoe. Excavators also provide more digging functionality because they can turn on their cab a full 360 degrees.

Backhoes are smaller excavating machines that offer more versatility but are typically seen on smaller construction projects like residential, snow removal, or loading jobs because of their limited dig depth potential. Whether you pick between a backhoe vs an excavator is dependent on the size of the job.

How deep can an excavator dig?

The depth capacity of an excavator will depend on the size of the equipment. Some specific kinds of excavators – like a long-reach model – make it easier to dig deeper than possible with a regular excavator. Typically, the heavier the operating weight of the excavator the deeper it can dig but it's always worth reviewing the specifications of the equipment before use.

What is the proper digging position for an excavator?

The proper position for digging with an excavator will differ depending on the terrain, the size of the equipment, the location of the dig site, and the nature of the job.

The best way to set up a dig for success is to take the time to plan before starting. Organizing where the scoop pile will go and where to stage other needed materials will keep the dig safe once it is started. Reading site plans to identify underground hazards like wires or pipes will ensure the productivity and efficiency of a job. Take time to paint lines before digging to align the first dig.

All of these steps help to create a safe working environment which is the first step to proper digging with an excavator.

Can I rent an excavator?

Yes, excavators can be rented for use. You can search DOZR Marketplace for excavators of all sizes to find an excavator rental near you. Rentals are available by the day, week, or month depending on your project length and needs.

The cost to rent an excavator changes depending on the length of the rental and who the supplier is. You can view all prices and compare them in the DOZR search results.

The largest excavator in the world. Magazine Construction Machinery and Equipment

The largest rotary excavator

The largest rotary mining excavator in the world until 1995 was Bagger 288, which was released in 1978. However, in the mid-1990s, the German company Takraf produced a huge Bagger 293 monster. From that moment, disputes began, who is bigger. Different sources give different sizes of models. So, the length of Bagger 288, according to some data, is 240 m, according to others - 220 m, while Bagger 293 in length reaches 225 m. The dimensions of the two machines are similar (height - 96 m, width - 46 m). The weight varies - 13,500 against 14,200 tons. From this fact, we can conclude that Bagger 293 still removed its predecessor from the pedestal.

Photo source: enki.uaThe dimensions of the Bagger 293 excavator are similar to the dimensions of the Egyptian pyramid of Cheops

The performance of the two excavators is the same, they are able to process 240,000 m 3 rock per day (18 buckets are installed on a rotor with a diameter of more than 21 m). It will take 3,822 KAMAZ trucks or 2,400 railway cars to take out the extracted minerals in one day.

Photo source: pinterest.com The approximate cost of Bagger 288 is $100,000,000

2000s had to overcome 22 km (the distance from one quarry to another). It took three weeks on the road. Almost 4 m wide 12-track tracks create minimal ground pressure, so the soil is not damaged when moving the colossus.

Photo source: gogetnews.info Bagger 293 is listed in the Guinness Book of Records as the largest land vehicle

It is known that the Bagger 288 bucket wheel excavator has 16 electric motors, which in total consume 16.5 MW. For comparison: this is how much electricity a small town needs.

Photo source: lazerhorse.orgBagger 293 and 288 are still working in German quarries to this day

Both machines are still working in German quarries today. To service a heavier instance, 5 workers are required at once, for Bagger 288 a team of 4 specialists is required. Directly on the installations there are workshops for its repair, a rest room and a bathroom.

To service a heavier instance, 5 workers are required at once, for Bagger 288 a team of 4 specialists is required. Directly on the installations there are workshops for its repair, a rest room and a bathroom.

Photo source: madiaspy.ru Bagger 288 service life set by the manufacturer is 100 years

Photo source: enki.ua

Big Muskie 4250W - the most powerful walking excavator. The weight of the giant is 13,000 tons, and two buses would fit in its bucket with a volume of 168 m 3 . The mining equipment operated from 1969 to 1999 24 hours a day, 7 days a week. For 30 years, the American machine has completely exhausted the coal reserves in the open pit of Central Ohio Coal's (460 million m 3 breed), after which the monster was dismantled and taken away. In view of this, Big Muskie cannot stand on the podium. In addition, some sources mention that at the first attempt to "walk" the supporting surfaces of the machine were deformed. Subsequently, the giant was moved along a pre-prepared track.

Photo source: hcea.net Approximate cost of Big Muskie 4250W - $25,000,000

Photo source: greatmeh.narod.ruThe excavator bucket is now stored in the Ohio State Museum

The domestic ESH 65.100 (Uralmash) can be considered the largest walking excavator in the world. Today it is operated in Siberia. The mass of the machine reaches almost 5.5 thousand tons. Bucket with a capacity of 65 m 3 is capable of digging the earth at a depth of 46 meters. The Russian giant is equipped with four electric motors with a total capacity of 9,000 kW.

Photo source: techstory.ru The largest operating walking excavator - ESH 65.100

The world's largest hydraulic excavator

The world's largest hydraulic excavator is the 980-ton Bucyrus Rh500, which was released in 1997. Then the equipment cost the customer $ 14 million. The most expensive of the entire configuration were two Cummins engines with a capacity of 2,300 hp. each (over $4 million).

Photo source: pinterest. comBucyrus Rh500 in 1997 cost about $14 million900 tons per hour). A fuel tank with a volume of 15,000 liters is installed on the equipment. The earthmoving giant is equipped with an engine oil heating system, so it can work in extremely harsh conditions. Since 2011, the Bucyrus Rh500 has been owned by Caterpillar. The heavy duty hydraulic excavator is now powered by 16-cylinder Cat 3516B or Cummins QSK60 diesel engines with 4,400 hp. (1800 rpm).

comBucyrus Rh500 in 1997 cost about $14 million900 tons per hour). A fuel tank with a volume of 15,000 liters is installed on the equipment. The earthmoving giant is equipped with an engine oil heating system, so it can work in extremely harsh conditions. Since 2011, the Bucyrus Rh500 has been owned by Caterpillar. The heavy duty hydraulic excavator is now powered by 16-cylinder Cat 3516B or Cummins QSK60 diesel engines with 4,400 hp. (1800 rpm).

Photo source: bergminer.blogspot.com.byBucyrus Rh500 fuel tank capacity - 15,000 l

The largest Russian excavator

EKG-32R is the most powerful domestic excavator. For 8 years, starting from 2009, 3 copies were produced and put into operation at the IZ-KARTEX named after P.G. Korobkov (OMZ) plant in St. Petersburg. A machine with a straight mechanical shovel with a power of 1,700 kW weighs 1,050 tons. The maximum load capacity is 240 tons, the bucket volume is 32 m0011 3 breed.

Photo source: techstory.ruApproximate cost of EKG-32R - $11,500,000

Hyundai HX300SL excavator: power and performance

30-ton excavators are the most demanded machines in construction. They are visible everywhere: during the construction of an embankment, when excavating land for pits and trenches, when moving materials and goods.

Hyundai HX300SL works not only with its immediate working equipment - a 1.5 m³ bucket, but also with other attachments: a hydraulic hammer, a drill, a vibratory hammer and sometimes equipment for felling trees. The power and maneuverability with which the excavator operates during operation are impressive. With its impressive characteristics, the car does not look huge at all: length - 10.74 m; width - 3.2 m; height - 3.32 m; bucket - 1.5 m³, and all this with a weight of 30.2 tons.

Special attention should be paid to the large glazing, which provides good visibility in all directions. Well, if the operator has looked at something, electronic assistants will come to his aid, who will notify him of the presence of foreign objects in the area of work being carried out. The wiper on the windshield does not restrict the view and, together with the glass, rises under the cab roof.

The wiper on the windshield does not restrict the view and, together with the glass, rises under the cab roof.

But the cabin itself is moved forward, beyond the fulcrum of the boom. The raised boom does not obscure the view, which creates conditions for calm and safe work. At the same time, when installing the excavator at the work site, one should take into account the considerable turning radius of the platform counterweight - 3.3 m.

The working conditions of the operator are well thought out. The cab is bright and spacious, not overloaded with controls, the operator has only the most necessary at hand. The effect of spaciousness is enhanced by light cladding and an abundance of natural light penetrating through large windows from all sides. There is plenty of legroom left. Armrests with joysticks are adjustable. The chair is mounted on a sled 300 mm long and moves along them along with the control consoles. The left control console rises almost vertically, allowing the operator to move freely around the cab. Even a large person sitting in a chair has a lot of space above his head and around his shoulders, because the width inside is 1.2 m with a height of 1.7 m. Many little things are provided: a cup holder, a socket for charging a mobile phone, various niches and, of course , modern audio system.

Even a large person sitting in a chair has a lot of space above his head and around his shoulders, because the width inside is 1.2 m with a height of 1.7 m. Many little things are provided: a cup holder, a socket for charging a mobile phone, various niches and, of course , modern audio system.

Simplicity and ease of control Hyundai HX300SL - the main difference from previous modifications. The excavator responds to joystick movements easily and smoothly, there is no sharpness or excessive sensitivity. An operator with little experience or who has moved from another machine will be able to quickly adapt to the new machine. Joystick control is distributed according to the standard European scheme: the left one is the handle and platform rotation, the right one is the boom and bucket. At the same time, the machine comes from the factory with a preset for 6 operating modes. The operator selects the appropriate mode or sets up the machine for himself in a special "custom" mode.

Hyundai equipment has been supplied to Russia for several days, and practice has shown that for operation in the middle lane there is no need to additionally “adapt” it. The standard equipment fully corresponds to the Russian climate, and for deliveries to regions with a colder climate, "arctic" preparation is carried out. Conditions for simple and safe daily and periodic maintenance are thought over. In order to prevent injuries, the manufacturer covered the fan with a circular grille, and installed a heat shield on the turbocharger. Daily service points are easily accessible from ground level, which has a positive effect on the speed of routine maintenance. And all external surfaces are coated with special anti-slip coatings.

The standard equipment fully corresponds to the Russian climate, and for deliveries to regions with a colder climate, "arctic" preparation is carried out. Conditions for simple and safe daily and periodic maintenance are thought over. In order to prevent injuries, the manufacturer covered the fan with a circular grille, and installed a heat shield on the turbocharger. Daily service points are easily accessible from ground level, which has a positive effect on the speed of routine maintenance. And all external surfaces are coated with special anti-slip coatings.

The Hyundai HX300SL excavator proved to be a powerful, productive and mobile machine, easy and convenient to operate and maintain.

- Operating weight - 30,200 kg.

- Engine — Hyundai HM8.3 in-line, 6-cylinder.

- Rated power - 248 hp With. at 1,900 rpm

- Dimensions - 10740 x 3200 x 3320 mm.

- Maximum digging depth 7330 mm.

- Maximum reach at ground level is 10,610 mm.