Construction site excavator

What is an excavator and what's it used for?

On virtually every construction site, you'll find at least one excavator. But what is an excavator? What do they do, and why are they integral to almost every Dirt World project? In simplest terms, excavators are large industrial machines used to move large amounts of material, like rock and soil. That means they do everything from digging a basement to laying pipe to mining.

But that's just the tip of the iceberg. We've got to get a little deeper to understand all the ways excavators are used and why they're so important in the Dirt World.

What is an excavator?

The next time you drive by a construction site, look for a big machine with a moveable boom with a bucket. It'll probably be on tracks or wheels, and it'll probably be busy moving a heavy amount of soil, gravel, or anything else that's a) heavy and b) needs to be moved elsewhere.

These machines use hydraulics to move the boom and bucket, not unlike how the steam shovels of yore used steam — but excavators are a lot quieter, more maneuverable, and much more eco-friendly.

What's an excavator used for?

Maybe the question should be, "what are excavators not used for?"

They can dig, haul, and — with the proper attachments — even boreholes and drive piles. But since we're digging deep, an excavator can be used to:

- Dig trenches, foundations, pools, or even graves

- Handle and haul material like soil and gravel

- Mine

- Dredge rivers

- Load haul trucks

And with the right kind of specialized attachment, excavators can:

- Break down other machinery when needed

- Cut trees and brush

- Create mulch

- Demolish buildings and other structures

- Drive piles and shafts

In short, they're a jack-of-all-trades around the job site, and that's why virtually every job site has at least one excavator on hand.

What’s the difference between an excavator and a backhoe?

One common misconception is that excavators and backhoes are the same, and they frequently get misidentified as one another. After all, excavators and backhoes look a lot alike to someone outside the Dirt World looking in. They're both (usually) on wheels or tracks, they both have buckets, and they're both used for just about everything.

But backhoes and excavators are very different machines used for very different jobs. There are three main differences between excavators and backhoes:

Size and Weight

Excavators are standalone machines that were built to, well, excavate. On the other hand, backhoes are often just attachments that mount on the front or rear of a conventional tractor by what's known as a king pivot (and they're still called "backhoes" even when mounted on the front). You can find backhoes on farms and smaller projects where less power and hauling capacity are needed. Because of their small size, utility companies will also use backhoes in tight urban environments.

You can find backhoes on farms and smaller projects where less power and hauling capacity are needed. Because of their small size, utility companies will also use backhoes in tight urban environments.

Versatility of Function

Backhoes come with a similar range of attachments as excavators, but since they also feature a front loader with a coupler, they become much more versatile. Here's a small selection of attachments:

- Augers

- Brooms

- Buckets

- Compactors

- Hammers

- Rippers

- Thumbs

- Pallet forks

- Rakes

- Snowplows

And while many of these can also be attached to excavators, most companies that operate excavators don't bother since they use purpose-built machinery to accomplish many of these same tasks.

Rotational Range

Since backhoes are mounted to the front or rear of conventional tractors, they don't have the same rotational range as excavators. Most backhoes can only rotate about 200 degrees or so, while excavators can rotate 360 degrees — in other words, a full circle.

Most backhoes can only rotate about 200 degrees or so, while excavators can rotate 360 degrees — in other words, a full circle.

What are the different types of excavators?

The range of excavator types is almost as diverse as the jobs the excavators perform. Let's look at the most common types you'll likely see on your next job site.

Crawler or Compact Excavators

Crawler excavators are everywhere, and they're probably what most people imagine when they think of the word "excavator." They're on tracks (like a tank), typically feature an enclosed cab, and use a hydraulically powered boom to dig through heavy material. They work in virtually every type of terrain — albeit slowly.

Pro: Being on tracks makes them sure-footed on uneven or muddy terrain.

Con: Being on tracks makes them slower than some other excavator types, especially on smooth surfaces like asphalt. The tracks are also much more expensive to maintain and can cause damage to asphalt or concrete pavement.

Wheeled Excavators

Wheeled excavators don't differ much from crawlers, aside from being on wheels rather than tracks. Wheels make them faster and more maneuverable on roads and other asphalt or concrete surfaces, making them unstable on muddy or hilly terrain. These wheeled excavators will often run around on large-scale highway projects where they frequently have to travel long distances between work.

Pro: They can mobilize from job to job faster.

Con: They're more useful on smooth surfaces and require a more skilled operator.

Long-Reach Excavators

Call on a long-reach excavator when you need to dig something that's in a hard-to-reach place. As you probably guessed, they're noteworthy for their long booms, which can reach material more than 100 feet away. You’ll often find long-reach excavators in dredging applications where the machine can’t get to the material without sinking.

Pro: Their long reach makes it easy to reach material in a difficult or awkward location.

Con: Their long boom makes them difficult to move and maneuver — and they take up a lot of space when not in use.

Ultra-High Demolition Excavator

Need to take down a super tall building with incredible precision? Bring in the UHD or ultra-high demolition excavator. These units are purpose-built demolition machines based around your typical excavator's chassis. They usually feature a massive two-piece boom in straight segments, a tilting cab, so the operator isn’t breaking their neck all day, and a larger undercarriage to stay more balanced with all the extra weight. These machines are great for taking down tall structures up to 200’ tall, but that massive reach allows the operator to demo the structure at a safe distance without being hit by debris.

Pro: They’re capable of taking down large buildings with ease.

Con: These machines have a much higher operating cost than most excavators and are a huge pain to transport.

Hydraulic Front Shovels

These massive machines may be standard in mining operations or the heaviest of civil construction projects, but you're not likely to encounter one on a job site. The buckets on these behemoths can hold up to 65 cubic yards of material — making hydraulic shovels just a little overkill for a typical Dirt World project.

Pro: Big

Con: Big

Suction or Vacuum Excavators

The others on this list are massive, earth-moving brutes, but the suction excavator is more like a surgeon's scalpel. The vacuum excavator system shines when digging around buried and active underground utilities. A typical excavator would likely damage these costly utilities, but a vacuum excavator is more gentle and precise. They utilize a pressurized water jet system, much like a pressure washer you’d use to clean your car, to break up the dirt. Then they suck it up with a giant metal hose and haul it away–this enables a suction excavator to extract material from a small area fast – at speeds of up to 200 miles an hour. You’ll most commonly find these mounted to on-road trucks that look like tankers with an elephant truck out front.

You’ll most commonly find these mounted to on-road trucks that look like tankers with an elephant truck out front.

Pro: They're good for precise underground operations, like pipes and drains.

Con: They suck — it's the only thing they do, so if you need a ton of loose soil moved from a large area, a suction excavator isn't much use.

Fun fact: the world's largest excavator is the Bagger 293, a bucket-wheel excavator. You won't see that variety of excavator in the field, though: it's the world's largest land vehicle at 315 feet tall, 738 feet long, and weighing in at an eye-watering 31.3 million pounds.

What are the common parts of an excavator?

What's an auger? Or a stick? Or a slew ring? Don't worry; we'll explain all the most common parts of an excavator so you can sound like an excavator expert on the job site.

- Bucket — The steel container at the end of the dipper or stick, used to lift and handle materials

- Linkage — Links the bucket to the dipper, provides vertical movement

- Dipper (or stick) — Attaches the linkage and bucket to the boom

- Boom — Raises or lowers the dipper or stick

- Cab — Where the operator sits and manipulates the excavator's controls

- Car Body — What the cab is mounted on (think "frame and chassis")

- Cylinders — The hydraulic mechanisms used to move the boom and dipper

- Engine — You know this one — it’s the powerplant and heart of the machine

- Tracks — The interlinked steel plates that the excavator runs on

- Sprockets — Connects to the final drives and rotates the tracks forward and backward

- Slew ring (or swing bear or swing bearing) — The circular metal ring enables the excavator to rotate in a circle.

Attaches the car body to the chassis

Attaches the car body to the chassis

Of course, there are more, but these are the parts you're most likely to see and maybe even interact with on the job site.

Learn more about the Dirt World.

The Dirt World is full of exciting machines like excavators. If you'd like to learn more about them and other aspects of the Dirt World, including industry news, expert insights, and best practices from the experts, download the BuildWitt app today. It's designed for the Dirt World.

Leica iCON site excavator Expert Insight

Author: Olga Papandreou

Construction companies are under increasing pressure to meet aggressive deadlines on slim budgets. This is challenging, especially for small family-owned businesses but also for large heavy and civil construction companies running compact excavators. Until now, machine-control solutions were mostly available for big machines due to their sizable investment for hardware and software. Now, Leica Geosystems bring the benefits of machine control to small-scale excavators with an affordable and intuitive solution that enables them to execute excavation designs more quickly, easily and accurately than ever before! This is an exciting solution and we could not wait to hear more about it from Matthias Schmidt, Manager Portfolio Field and GNSS, and Morten Nissen, Product Manager Earthmoving. After a discussion with them, we are summarizing the five ways the new iCON site excavator can improve how companies utilise their compact excavators and their operators.

After a discussion with them, we are summarizing the five ways the new iCON site excavator can improve how companies utilise their compact excavators and their operators.

1. It makes digital construction and machine-control technology more accessible.

It has been proven that 3D machine-control solutions can bring significant benefits to heavy construction operations by providing more efficient and productive ways to work with construction machines. But systems sophistication and the up-front investment have been limiting factors for small-scale machines. In response, Leica Geosystems have specifically developed iCON site excavator to be an affordable, intuitive and easy-to-learn entry point into digital construction and machine-control technology – without sacrificing functionality. The result is an intelligent and accessible solution for small construction companies and rental companies deploying small excavators. The solution is suitable for all compact excavators with swing boom, tilt rotator or tilt bucket functionalities that could benefit from the precision of 3D machine-control technology.

2. The operator is no longer 'just the operator'.

When the iCON site excavator is used in conjunction with other iCON site applications, small-machine operators can autonomously execute more tasks than ever before – and within the same system. This solution empowers machine operators to do so much more than just move dirt, which streamlines production and labour costs. For example, an operator could start a project by generating a design in the existing software – drawing a simple design in the Sketch application or creating surfaces from as-built points in the Measure or Slope applications. Once excavation begins based on these plans, the operator can measure as-built points using the iCON site excavator’s as-built logging capability, which uses the tip of the bucket as a measurement device. Alternatively, the operator can use the As-Built application to check the final result against the design, using a Smart Antenna.

3. The hardware is specifically designed for compact excavators.

The hardware is specifically designed for compact excavators.

In addition to meeting a justifiable price point for smaller machines, the solution’s engineers have ruthlessly streamlined its hardware. The Leica iCON gps 100 dual GNSS machine receiver is compact and its installation requires minimal parts and cables, which is perfect for machines with limited cabin space. The Leica CR50 communication unit comes as optional, allowing customers to invest only in what they really need – with the possibility to easily upgrade and adjust to different site and project conditions. The Leica CR50 is ideal when using a local base station network with poor on-site coverage, which makes it difficult for crews to communicate without an external GSM antenna or UFH radio. Once the equipment has been installed, users no longer require physical access to the hardware for set up, configuration or software updates. The web interface allows remote access to the device for convenient and fast support. Despite the fact that the new hardware its compact and scalable, they use the latest technology, which enables them to use the tablet’s built-in modem. Additionally. services such as SmartLink Fill are available for the best customer experience and less disturbances in case of RTK outages.

Despite the fact that the new hardware its compact and scalable, they use the latest technology, which enables them to use the tablet’s built-in modem. Additionally. services such as SmartLink Fill are available for the best customer experience and less disturbances in case of RTK outages.

4. Compact excavators can enter the digital game of connected construction sites.

The iCON site excavator enables compact excavators to work with the same digital designs and impressive accuracy as the big machines. This ensures consistent standards of work and faster completion times on large projects because every machine on the construction site can work from the same plan. Any project and design updates can be now shared with all machines - independent of size - making sure every operator is informed and working based on the latest project data.

5. The Leica iCON site excavator solution easily integrates to other Leica Geosystems solutions.

Leica’s iCON site excavator is available as a standalone application or as an add-on to the existing and well-established iCON site software with loads of practical applications for heavy construction jobs. Existing customers will benefit from another tool that will increase equipment utilisation and achieve a quicker ROI. This is particularly applicable to construction companies already executing measurement and positioning tasks using Leica iCON site software and iCON Smart Antennas. Another example of a solution that can be used is the Leica ConX cloud platform. Leica ConX is a particularly powerful when it comes to progress reporting as it can transfer crucial information from multiple systems back to the office for administrative use. Additionally, ConX allows remote support to operators when they need help to troubleshoot or simply have a questions about the system set up.

Summary: a versatile and connected solution for increased efficiency.

Leica’s iCON site excavator opens up new possibilities to heavy construction companies that deploy compact excavators. The solution is a simple, easy-to-use machine-control solution for optimising the earthmoving jobs of compact excavators. It integrates easily to the existing iCON site applications, so you can benefit from new workflows that combine measuring, stakeout, excavating, and reporting in one easy package - with a quick ROI. And maybe the best news for customers that own compact excavators and iCON equipment such as field controller, software and Smart Antennas!

The solution is a simple, easy-to-use machine-control solution for optimising the earthmoving jobs of compact excavators. It integrates easily to the existing iCON site applications, so you can benefit from new workflows that combine measuring, stakeout, excavating, and reporting in one easy package - with a quick ROI. And maybe the best news for customers that own compact excavators and iCON equipment such as field controller, software and Smart Antennas!

construction excavator game on the App StoreDescription of

Enjoy excavator driving on hilly trails and drive heavy machinery with realistic physics controls of dump truck, heavy excavator and loader.

Welcome to excavator games 2020. It's time to work with loader to become a real excavator operator and steep hill builder. This heavy crane excavator game will bring you real offroad challenging games. In this game you have to drive heavy machinery in steep hill climb areas. Excavator Games 2019will offer you to drive your backhoe loader and dump truck to transport dirt and stones from one place to another in order to clear the road.

Excavator Games 2019will offer you to drive your backhoe loader and dump truck to transport dirt and stones from one place to another in order to clear the road.

In this heavy crane excavator game you will have to play the role of crane operator or loader and dump truck driver in hilly offroad area. You may have played truck games, trailer driving games and loader simulator but this excavator simulator is really challenging and really daring for beginners. Use your professional heavy machinery operation skills and enjoy the amazing drive excavator trailer rescue simulator on the steep hilly tracks. Every child dreams of driving heavy excavators and cranes. So this excavator simulator 2020 is the best driver and parking simulator games for young, teenagers and mature people who love to play and control such machines.

Sometimes we often encounter natural disasters happening every now and then, there will always be casualties, effects, and survivors. Why don't you be part of offroad adventure rescue excavator team in this extreme dump truck driver. So get ready and use your unique heavy machinery operation skills to help some survivors in this excavator games 2020. This is not some ordinary dump truck games but you actually have to work on construction sites with huge construction machines like excavator crane and a dump truck. In truck driving simulator 2020 game you will have to test your driving and excavator operating skills on offroad construction sites, if you can handle all kinds of construction vehicles and drive heavy vehicles with care then this loader simulator game is for you.

So get ready and use your unique heavy machinery operation skills to help some survivors in this excavator games 2020. This is not some ordinary dump truck games but you actually have to work on construction sites with huge construction machines like excavator crane and a dump truck. In truck driving simulator 2020 game you will have to test your driving and excavator operating skills on offroad construction sites, if you can handle all kinds of construction vehicles and drive heavy vehicles with care then this loader simulator game is for you.

Functions:

Amazing off-road scenery.

Smooth real truck driving control game. The

sand excavator and loader are extremely easy to handle.

Realistic weather conditions, sunny day or rain.

Detailed interior.

- Different camera angles make trailer parking much easier.

Version 1.2

- Improved performance

- more interesting gameplay

- problems with control

Ratings and reviews

ratings: 546

This game is a school homework assignment for programming?

I haven't seen such games for a long time. How can you ask for payment for this? Here the developer has to pay the players

Developer Asphalt Crack Studio Pty Ltd has indicated that, in accordance with the application's privacy policy, data may be processed as described below. Detailed information is available in the developer's privacy policy.

Data used for tracking information

The following data may be used to track user information in apps and websites owned by other companies:

- Geoposition

- Identifiers

- Usage Data

- Diagnostics

Related with user data

The following data may be collected that is related to the user's identity:

- Geoposition

- Identifiers

- Usage Data

- Diagnostics

Unrelated with user data

The following data may be collected, which is not related to the user's identity:

Sensitive data may be used differently depending on your age, features involved, or other factors.![]() Read more

Read more

Information

- Provider

- Asphalt Crack Studio Pty Ltd

- Size

- 142.2 MB

- Category

- Games

- Age

- 4+

- Copyright

- © Asphalt Crack Studio Pty Ltd 2020

- Price

- Free

- Developer site

- App support

- Privacy Policy

Supported

You may like

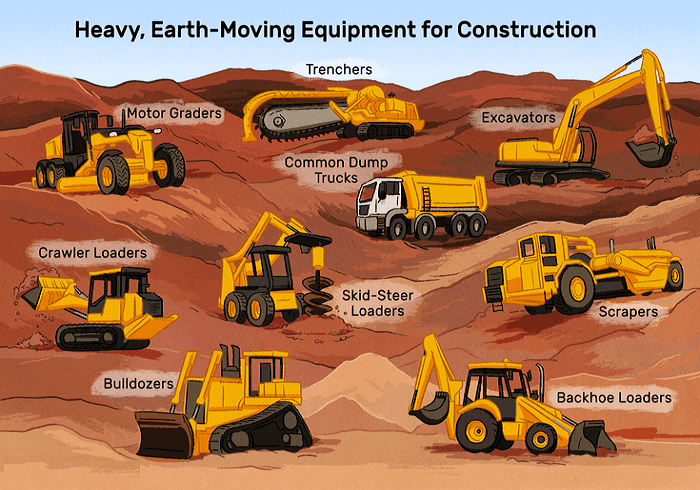

special earthmoving equipment, KOMATSU, LIEBHERR, VOLVO

The excavator belongs to special construction equipment, namely earthmoving vehicles. Although their main purpose is to work with different types of soil, they are also in demand as loaders. Excavators are in particular demand at construction sites, in the mining industry and in public utilities.

Although their main purpose is to work with different types of soil, they are also in demand as loaders. Excavators are in particular demand at construction sites, in the mining industry and in public utilities.

Classification of excavators

Based on the specifics of use, excavators are divided into several main types.

- backhoe loaders

- construction excavators

- mining excavators

- overburden excavators

- mine excavators

JCB JS145-W excavator 0.32-0.8 m3 bucket

types of excavators are divided according to the principle of operation into three types:

- single-bucket

- multi-bucket

- vacuum

The most popular, one might say, universal machines are single-bucket excavators. A distinctive feature of such machines is the immobility of the transport during the work, the bucket works with the help of excavator mechanisms. The bucket of this type of excavator can be either conventional or with an opening bottom. Usually the latter are used by the mining industry. They can also be part-turn and full-turn. The first include excavators with the ability to turn up to 90°, while the latter can allow repeated 360° rotation.

Usually the latter are used by the mining industry. They can also be part-turn and full-turn. The first include excavators with the ability to turn up to 90°, while the latter can allow repeated 360° rotation.

Wheel excavator TVEKS EK-14 (RUSSIA).

Continuous excavators include multi-bucket machines. This specific type of equipment is in demand in the development of homogeneous soft soils. Bucket excavators have much greater productivity due to the simultaneous digging and unloading of the soil.

Types of excavator propellers

Based on the type of power equipment and type of chassis, excavators can be electric, diesel, hydraulic or combined. There are many types of excavators according to the type of chassis, but the main ones can be distinguished:

- Wheeled

- Crawler

- Rail

- Walking

- Floating

- Underground

- Pneumatic Wheeled

Wheeled excavators can be tractor- or vehicle-based, so they are popular for urban work, be it any construction or utility work. They do not need to be transported as caterpillars, they are quite maneuverable, mobile and have good speed qualities.

They do not need to be transported as caterpillars, they are quite maneuverable, mobile and have good speed qualities.

As for crawler excavators, given their high cross-country ability, there is no better alternative for off-road use. At the same time, different types of caterpillars can be installed on modern crawler excavators, depending on the terrain and types of work.

Floating excavators are used for cleaning ponds, extracting sand and gravel, usually for work in swamps and water meadows. Heavy walking hydraulic excavators are in demand in the mining industry and large-scale construction sites.

In public utilities, preference is given to tractor and pneumatic wheel excavators with outriggers. As a rule, they are not powerful enough and do not have a large bucket, but this is quite enough to carry out repair utility problems.

Mini excavator Wacker Neuson 9503

Engine model: TCD 2012 L04 Diesel 4-cylinder (DEUTZ)

Overall dimensions: 6847x2465x2980 mm

Popular models of excavators

conditions and work.