Construction scoop truck

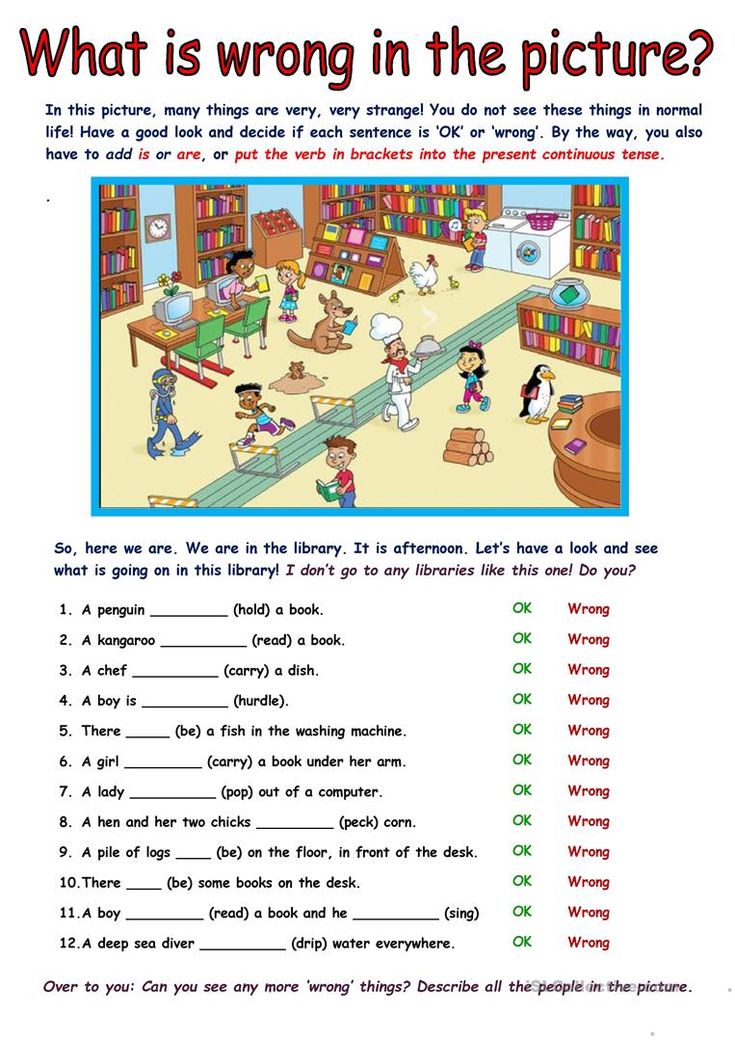

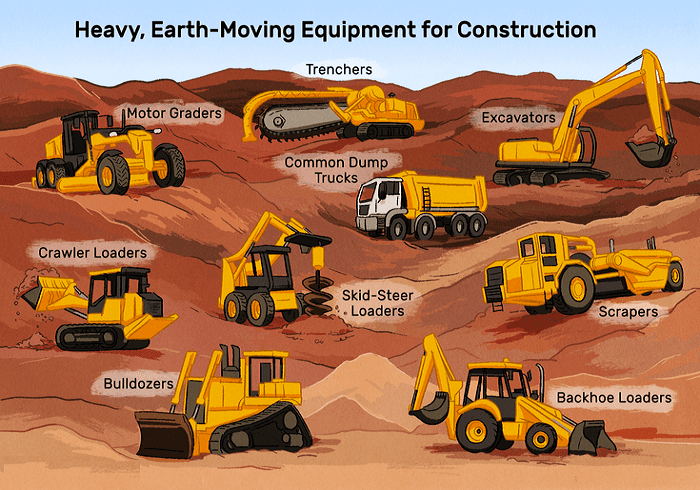

19 Different Types of Construction Vehicles

Be it excavation, dumping, or lifting, construction work includes moving heavy loads. It is not humanly possible to lift tons of weight without the help of any heavy machinery and vehicles. Construction vehicles are essential for all types of construction jobs, regardless of the size and scale. Whether it is the construction of a home building, or a large scale civil or commercial project, construction vehicles are a necessity.

Contents

- Types of Construction Vehicle

- 1. Bulldozers

- 2. Front Loaders

- 3. Dump Trucks

- 4. Backhoes

- 5. Grader

- 6. Trenchers

- 7. Cranes

- 8. Loaders

- 9. Crawler Dozers

- 10. Compactors

- 11. Excavators

- 12. Forklifts

- 13. Conveyors

- 14. Concrete Mixer Truck

As mentioned earlier, there’s a lot that needs to be done in the construction industry. With that being said, each of these tasks requires a different type of construction vehicle. There are many types of construction vehicles and almost all are used at some point at a construction site. Different types of construction trucks have been listed down below:

Bulldozer is the most common, most widely known, and the most-reliable type of construction vehicle. It is also the strongest among all other types. It wouldn’t be wrong to say that a bulldozer is basically a tractor with a huge blade fitted at the front. The metal blade which is characteristic of a bulldozer is powerful enough to drive a massive magnitude of sand, soil, debris, etc.

Bulldozers have an exceptional grip to the ground. They can be easily mobilized even on a patchy terrain. Bulldozers have wide tracks that are arranged over a vast area, distributing the weight of the gigantic construction vehicles. As a result, the pressure applied is greatly decreased.

Bulldozers have a torque divider that transforms the engine power into significant dragging capability, that allows them to tow heavy tanks with great ease. Bulldozers are used to remove obstacles, debris, bushes, trees, and to clear roads. They can also be employed to dig trenches, in military operations, and farming works.

Bulldozers are used to remove obstacles, debris, bushes, trees, and to clear roads. They can also be employed to dig trenches, in military operations, and farming works.

A front loader is an earth moving equipment, that is also known as scoop loader, bucket loader, front-end loader, or front loader. Front loaders are similar to a bulldozer, only further away from the ground. They have huge wheels that make them suitable to be used in extremely rough terrains. They have moveable arm with a wide square bucket which is used to move material around. The bucket may be permanently attached or it may be removable. Sometimes, the bucket is replaced with other tools such as hydraulically operated bucket or forks.

The primary purpose of front loaders is moving dirt. They are used in construction sites and when roads are being fixed. Front loaders are used for the transport of building materials such as bricks, metal bars, pipes, and digging tools. They are also used for snow removal.

They are also used for snow removal.

A dump truck is one of the most popular types of construction vehicles. Dump trucks are primarily used to dump debris away from the construction site. They can also be used to bring additional construction material to the construction site.

There are many types of dump trucks that are available.

Off-Road Dump TrucksThey are also known as articulated trucks. They are huge construction vehicles that are used for mining operations where significant amounts of aggregate have to be hauled. They are ideal to be used off-road, that is, on rough terrain.

Transfer Dump TrucksTransfer dump trucks are a type of trucks that are pulled by a separate trailer. The trailer has a movable cargo container. It greatly increases the load capacity of the vehicle without affecting the maneuverability.

Side Dump TrucksThey are the fastest dump trucks for unloading huge amounts of debris. They are preferred on sites where there is a lot of space to maneuver because of their length. They tilt on the side for dumping and have a lower risk of tipping over.

They are preferred on sites where there is a lot of space to maneuver because of their length. They tilt on the side for dumping and have a lower risk of tipping over.

The standard dump truck is the most commonly used dump truck at the construction sites. They cannot be used on soft soils. They have great maneuverability.

4. BackhoesBackhoes is another type of construction vehicle that is used to move the earth. Backhoes can be mounted on a regular tractor or a front loader. They are used at the construction sites to dig trenches and ditches for laying cables, pipes, and foundations. It can excavate dirt and also move snow.

Backhoes can travel to rough terrains where other construction vehicles may not be able to travel. They can be used to clean the construction site, dig deep-rooted tree roots, and trees. They can pat down any loose soil. Moreover, backhoes can also be used to plant trees and dig post holes.

Graders, also known as road graders or motor graders, are heavy equipment construction vehicle that has a long blade. The primary purpose of a grader is to remove any small amounts of dirt and create flat surfaces. Graders are usually used for the construction of roads and construction and maintenance of gravel roads and dirt roads.

Graders are also used to prepare the base court of paved roads for the creation of a wide, flat surface on which the asphalt is placed. They are also used to set native soil foundation pads before the construction of large buildings.

6. TrenchersTrenchers are a very versatile construction vehicle that can be used for a variety of purposes. Its flexibility makes it popular. Trenchers can be used for digging trenches, laying pipes, installing drainage, and for the preparation of trench warfare.

There are different types of trenchers, which are:

Chain TrenchersChain trenchers consist of a digging chain and a track trencher. They are used to cut ground and to form deep and narrow trenches.

They are used to cut ground and to form deep and narrow trenches.

Wheel trenchers consist of a toothed metal wheel. They are used to cut pavements during road maintenance. Construction companies use wheel trenchers to gain access to under road utilities.

Micro TrenchersMicro trenchers are used when construction work has to be carried out in urban areas. The cutting wheel in micro trenchers cut micro trenches, rather than huge trenches that would disrupt the urban routine.

7. CranesCranes are one of the most useful construction vehicles. They are composed of pulleys and cables that allow them to lower and lift loads beyond the capabilities of humans. They do not just help in lowering and lifting loads, they also move material horizontally. Construction companies use cranes at the construction sites to aid the movement of heavy materials, which human workers cannot move about.

Cranes can be static or mobile. Mobile cranes have large wheels to provide stability and support to the crane while it is raised high, holding a heavy load. Tower cranes are a commonly used type of crane in the construction of tall buildings.

8. LoadersAs the name indicates, loaders are used to load materials. Loaders are used at construction sites to not just load but also move construction materials around. They are used to load and move materials like dirt, snow, asphalt, demolition debris, gravel, recycled materials, and rocks.

Loaders may be wheeled or tracked. Wheeled loaders are more like mobile shovels that aid in the transfer of material from stockpiles on the ground to trucks and transport them around the construction site. Loaders may be of different types including front loaders, bucket loaders, skid-steer loaders, payloaders, and scoop loaders. Every type of loader has a different use.

The assembly of a loader can vary. They can either be permanently mounted or they can have a removable attachment. The bucket can be augmented as well.

They can either be permanently mounted or they can have a removable attachment. The bucket can be augmented as well.

Crawler dozers are one of the most powerful construction vehicles. Crawler dozers are tracked vehicles that have excellent stability. They have a variety of blades mounted on its front that help in moving material. They are very often used in pioneer work, such as laying new roadways or to remove overburden during mining. Smaller crawler dozers are used as grading tractors or for using automated grade controls for the establishment of complex contours.

10. CompactorsIf you do not have adequate soil compaction, there could be an erosion of the foundation, pipe breaks, and leakages, and slab cracks. These problems can result in structural failure and an unnecessary increase in maintenance costs. The better the foundation, the better is the building. A compactor is, therefore, a very important construction vehicle that is used for soil compaction. No matter how big or small a construction project is, a compactor is a necessary construction vehicle.

A compactor is, therefore, a very important construction vehicle that is used for soil compaction. No matter how big or small a construction project is, a compactor is a necessary construction vehicle.

Compactors are of different types. There is baler-wrapper compactor that is used to make compact bales, a trash compactor that is used to reduce the volume of the trash, vibrating plate compactor that is used in narrow areas hard to maneuver, rammers that are used to make trenches, smooth rollers that are used during road constructions, and many more. Smooth rollers are the most commonly used type of compactors.

11. ExcavatorsExcavation is the primary activity that takes place at every construction site. The excavation is so large-scale that heavy excavation equipment is needed. Excavators are one of the most valuable construction vehicles.

An excavator consists of a bucket, boom, dipper, and a cab that is located on a rotating platform (house). The house sits on the top of tracked or wheeled undercarriage. They come in many sizes; the smaller ones are called compact excavators or mini excavators.

The house sits on the top of tracked or wheeled undercarriage. They come in many sizes; the smaller ones are called compact excavators or mini excavators.

Excavators are used for the digging holes, trenches, and foundations. presence of hydraulic hammers makes them more efficient and effective than any of the other excavation equipment. They are used in almost all industries, including mining, construction, forestry, demolition, material handling, dredging rivers, or simply to lift heavy objects.

12. ForkliftsForklifts are a very powerful construction vehicle. They are used to move heavy loads around the construction site or in a warehouse. They aid in lifting and transporting objects that a human cannot move. It makes forklifts an indispensable vehicle at all job sites.

There are many types of forklifts, each having a different load capacity. The types range from simple pallet jack to industrial telehandler. The difference in all types is the maximum weight they can lift.

The operator cannot just raise or lower the forks or blades, but they can also be tilted to compensate for loads that have a tendency to angle the blades towards the ground and increase the risk of slipping.

13. ConveyorsConveyors are machines that are used to convey materials from one spot to the other. They can be used to move materials of any shape, size, and weight. Conveyor systems are used in numerous industries including agriculture, automotive, mining, electronic, aerospace, pharmaceutical, food processing, print finishing, bottling and canning, and packaging.

You must be wondering why we are considering a conveyor as a construction vehicle. Sometimes, the shaft of the conveyor is supported by wheels which allow the movement of the shaft, around a construction site. Wheeled conveyors can be seen at construction sites commonly to move bulky stones and bricks from one point to the other.

14. Concrete Mixer TruckA mixer truck is a construction vehicle that combines cement, sand or gravel, and water homogenously to form concrete. A mixer truck consists of a revolving drum mounted on the truck that mixes all components together.

A mixer truck consists of a revolving drum mounted on the truck that mixes all components together.

When smaller quantities of cement are needed at a construction n site, a portable concrete mixer (concrete mixer truck) is often used. It provides the workers enough time to use the concrete before it gets hard.

Construction vehicles are necessary for any construction project. Despite the presence of numerous laborers at the site, it is not possible for human workers to do everything by hand. The use of construction vehicles and construction equipment does not just speed up the construction process but also helps workers by making their jobs less laborious and strenuous.

Construction Scoop - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(79 relevant results)

on the chassis:

KamAZ dump trucks

MAZ

dump trucks Volvo

SCANIA

Mercedes

dump truck

Samolets Samoil

15 cube dump truck

16 cube dump truck

20 cube dump truck

25 cube dump truck

35 cube dump truck

for carrying capacity:

Self -Self 10 tons

dump truck 15 tons

dump truck 20 tons

by the number of axes:

Two -axle dump trucks

Trex dump trucks

Four -axle dump trucks

26 m 3 /33 m 3

Bestseller Dump truck AMKAR-658983-01on FAW chassis

Ask for price Add to Compare

nine0065

20 m 3 /26 m 3

Bestseller Dump truck AMKAR-558983on FAW chassis

Ask for price Add to Compare

5 m 3

Dump truck AMKAR 658983-04on chassis FAW

Ask for price Add to Compare

20 m 3

Dump truck AMKAR 658981on Shacman chassis

Ask for price Add to Compare

19 m 3

Dump truck AMKAR-6589Eon KAMAZ chassis

Ask for price Add to Compare

16 m 3

Dump truck AMKAR-6589-07Eon KAMAZ chassis

Ask for price Add to Compare

12 m 3

Dump truck AMKAR-658901Eon KAMAZ chassis

Ask for price Add to Compare

15 m 3

Dump truck AMKAR-658901MEon KAMAZ chassis

Ask for price Add to Compare

7 m 3

Dump truck AMKAR-658902Eon KAMAZ chassis

Ask for price Add to Compare

7 m 3

Dump truck AMKAR-658902-10Eon KAMAZ chassis nine0002 Ask for price Add to Compare

14 m 3

Dump truck AMKAR-658902-10Eon KAMAZ chassis

Ask for price Add to Compare

7 m 3

Dump truck AMKAR-658902-10E with space for CMUon KAMAZ chassis

Ask for price Add to Compare

12 m 3 /16 m 3

Dump truck AMKAR-AM659-01Eon ISUZU chassis

Ask for price Add to Compare

16 m 3 /20 m 3

Dump truck AMKAR-658991-01Eon HINO chassis

Ask for price Add to Compare

16 m 3

Dump truck AMKAR-658991-02Eon HINO chassis

Ask for price Add to Compare

10 m 3

Dump truck AMKAR-65892-03Eon MAN chassis

Ask for price Add to Compare

7 m 3

Dump truck AMKAR-65896-01Eon Mercedes chassis

Ask for price Add to Compare

16 m 3

Dump truck AMKAR-65896-03Eon Mercedes chassis

Ask for price Add to Compare

26 m 3

Dump truck AMKAR-65896-02Eon Mercedes chassis

Ask for price Add to Compare

12 m 3

Dump truck AMKAR-658961-02Eon SCANIA chassis

Ask for price Add to Compare

12 m 3

Dump truck AMKAR-658966Eon TATRA chassis

Ask for price Add to Compare

18 m 3

Dump truck AMKAR-658982Eon CAMC chassis

Ask for price Add to Compare

25 m 3

Dump truck AMKAR-658982-05Eon CAMC chassis

Ask for price Add to Compare

5 features of choosing large vehicles

Dump truck is an indispensable equipment in construction and cargo transportation. To purchase high-quality equipment that will serve the owner for a long time. It is necessary not only to carefully maintain it, but also to be aware of the features that can affect the life and performance of the vehicle. nine0003

To purchase high-quality equipment that will serve the owner for a long time. It is necessary not only to carefully maintain it, but also to be aware of the features that can affect the life and performance of the vehicle. nine0003

Distinctive features

The dump truck differs from an ordinary truck in that it was originally created for independent unloading of any cargo. In this regard, three types of possible unloading are immediately distinguished:

- from three sides;

- on both sides;

- classic rear loading.

Which option to choose depends on the type and location of the machine.

How to choose the unloading option?

This is the first feature to consider when choosing a dump truck. Each of the options should be considered in as much detail as possible:

- Rear dump. They are also called quarry, as they are most often used to work in these places. Coal is often transported on such machines.

- Double dump trucks are popular in agriculture.

In some cases, farmers buy equipment with unloading from three sides. It all depends on personal needs and the intended type of goods transported.

In some cases, farmers buy equipment with unloading from three sides. It all depends on personal needs and the intended type of goods transported. - 3-way dump trucks, typically used in the construction and maintenance industries. For example, during the construction or reconstruction of highways, therefore they are also called road. nine0453

Focusing on the purpose for which you need equipment and you should choose the best dump truck. It is also worth paying attention to the shape of the body. It happens with a square, oval section or in the form of a square with a front wall located under a slope.

Please note that if you intend to use the truck in winter, it is better to provide that the body is equipped with heating. So the cargo will not freeze.

Operating weight

The second factor is the weight that the machine can carry. According to the load capacity, these trucks are divided into the following categories:

- up to 1 ton;

- from 1 to 2 tons;

- from 2 to 5 tons;

- from 5 to 10 tons.

The rarest variety is dump trucks capable of carrying loads of more than 10 tons. Most often they are made by special order, if the client has a need for just such a powerful technique.

Type of axle load

This is the factor that distinguishes the number of axles in the truck. This is important, since the entire load is distributed between them.

A maximum of 7 axles per dump truck. These are trucks of the most impressive size, working in quarries. nine0003

Two-axis and four-axis machines are more common in construction and agriculture.

Dimensions

There are a wide variety of dump trucks in terms of size and dimensions.

Medium-sized dump trucks are the most common in the construction industry. The largest work in quarries. As a rule, the carrying capacity depends on the dimensions. In most cases, these are two interrelated factors.

Manufacturer

This factor affects not only the appearance of the car, but also its reliability and performance.![]()