Diy box truck

Unique DIY Box Truck And Retired Ambulance Conversions

- By Kate Moore

- on

- This post may contain affiliate links. As an Amazon Associate, I earn from qualifying purchases. Please read my full disclosure.

Box truck and ambulance conversions offer a rectangular frame with straight edges and plenty of interior space. That makes them one of the best camper vans for van lifers who want a little extra room–not to mention the cool factor!

We’ve pulled together some of the coziest, most modern, and unique conversions on the internet for your inspiration.

Who knows? Maybe the next time you see a retired ambulance for sale, you’ll consider it for life on the road.

DIY Retired Ambulance Conversions

image courtesy of @fornya_design_coSince 2006, Fornya Design Co has been building, restoring, and designing custom vehicles. This conversion is a 2006 Ford E350 Turbo Diesel Fire Rescue perfect for adventure!

We like the simple metal and wood design This camper comes equipped with an indoor/outdoor shower, and a cassette toilet for when you’re off the grid.

The vehicle utilizes both shore power and a generator to run a fridge/freezer combo, Maxxair fan, and Mach 10 air conditioner.

image courtesy of @dogs_in_a_pickleBen and Jenna wanted a custom-built ambulance camper to travel with their three dogs. We like this cozy interior with plenty of seating and storage space.

The ambulance was designed by a semi-retired engineer at Criftin’s Campers in North Shropshire, UK.

image courtesy of @ambulance_conversionOne of our favorite modern retired ambulance conversions is this design by Steve and Eva. The ambulance itself is a 1999 Chevy 3500, 4×4, with a 6.5 Detroit diesel engine.

The ambulance has a designated bathroom and huge kitchen. The sink and shower are heated with an electric Bosch water heater.

image courtesy of @brian.sirinBrian built this custom 1995 E350 Ambo Conversion to travel with his son. The simple design has a queen-sized bed, composting toilet, two water tanks for a sink/shower, and a 12v refrigerator.

The ambulance is still a work in progress, but there’s enough complete to go on some epic adventures.

image courtesy of @adventure_amboThis self-converted 1995 F350 Adventure Ambulance has a modern and spacious style so you can relax inside and out.

There is lot’s of hidden gear storage in this truck with multiple locking exterior boxes, a slide-out table, extra storage under the seats, and a small closet.

DIY Box Truck Conversions

image courtesy of @vanlife_with_ethelGuy is an ex-surveyor who spent nearly $15,000 converting a former horse box. The interior is designed mainly with Douglas fir giving it a comfortable aura.

A wrap-around couch at the back leaves plenty of room for multiple friends to enjoy the view out the back window and relax in the evening. There’s also a lofted bed, mini fireplace, and small kitchen complete with a sink, oven, and stove.

image courtesy of @offthemainroad_One of the more basic and beautiful box truck builds we’ve come across is this design by Charlotte and Ken.

This oversized truck has a Mercedes Sprinter base and inside you’ll find a shower, toilet, four-burner gas stove, refrigerator and full-sized bed.

image courtesy of @butitsonourlistJeff and Alyssa designed this custom box truck conversion out of a Ford E450. The truck has a spacious kitchen and dinette, dedicated bathroom with interior shower, and it’s powered with a mix of solar and shore power.

The Most Unique House Truck Conversion

image courtesy of @the_ugly_trucklingOne of the most unique builds we’ve seen is this house truck art project by Kai. The base is a 5-ton truck with a modified frame. Kai says:

“The frame has been extended and dropped behind the rear axle for added head room in the interior of the house. It is illegal to modify a trucks frame between the axle, but welding behind the rear axle doesn’t effect the structural integrity of the frame.”

The Ugly Truckling has many one-of-a-kind features including dutch doors, stained-glass windows, antique locks and cedar exterior.

Inside you’ll find a cozy, mini wood-burning stove, Girard on-demand tankless water heater, couch, loft, and kitchen!

Check out these other unique designs:

- Inspiring school bus conversions

- Dodge ProMaster conversion ideas

- Mercedes Sprinter conversion ideas

- Ford Transit conversion ideas

Kate Moore

Kate is the lead content creator for ParkedInParadise.com and has spent over two years living in a camper van conversion. She has traveled through 48 US states and writes about van life, camping and RV living.

6 Jaw-Dropping Box Truck Camper Conversions

*This post may contain affiliate links, which means I may earn a small commission at no extra cost to you. Please read our disclosure policy for more info.

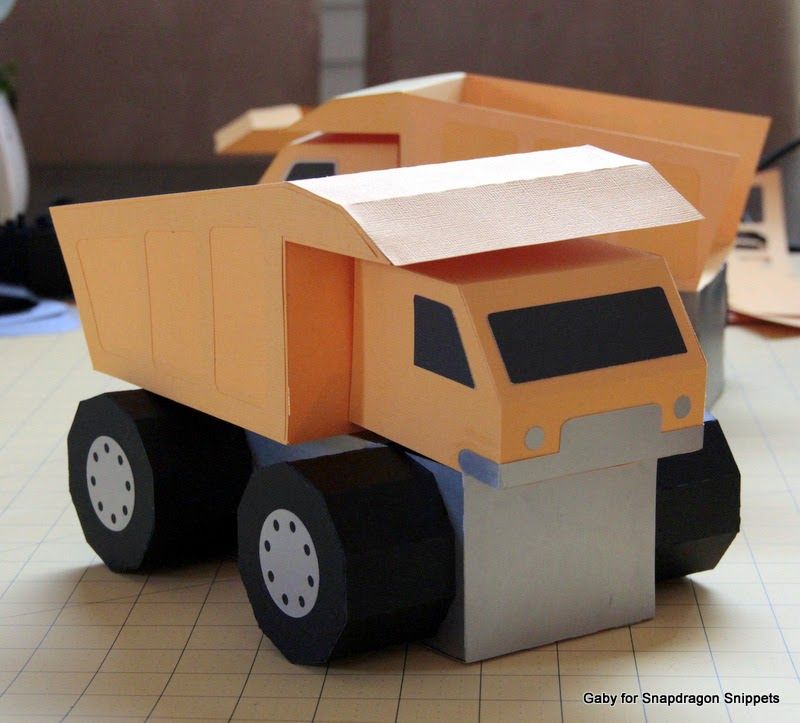

Even though you don’t see many around on the road, box truck camper conversions make for the ideal RV for the van lifer on a budget.

Box trucks are cheap and easy to obtain, as they are used by professionals, such a plumbers and movers, and you can even buy retired service vehicles, like ambulances, at your local town office.

Thanks to their rectangular shape, box trucks are also highly customizable, leaving you plenty of freedom for the floor plan design.

Many box truck camper conversions feature enough headroom to stand up and some are four-wheel drive, which is always a plus. To keep your box truck camper conversion costs to a minimum, you could do it all, or in part, DIY.

Alternatively, you can use a box truck camper conversion company, such as Contravans, to cut down on the work you need to do.

With a box van conversion, you decide exactly how far you want to take the build: will you need a wet bath in your box truck conversion interior? Are lithium batteries essential to your van adventures?

No need to commit to a specific number of options for your box van camper – you can make an initial gear choice and then add things on as you feel the need for them.

While a box truck may not look especially attractive in its pure form, a box van camper conversion can really transform them into a fantastic tiny house on the road.

Need some evidence? Check out these jaw-dropping box truck camper conversions.

Table of Contents

Tegan’s Modern Rustic Box Truck Camper Conversion ‘Marcel’

When you enter Tegan’s 92 GMC Vandura, you will feel the hygge-filled design’s warm hug all around you. The whole box truck camper conversion interior is lined with wooden panels, giving the interior a rustic, scandi feel.

The floor plan includes a couch bed and a kitchenette with an oven, hob, sink and cooler.

To aid ventilation, already provided by a hatch in the roof, there is a small window by the hob. This allows Tegan to cook while admiring the wild landscapes she travels to.

There are also some clever features on board, such as the slide-out table and the ceiling jar rack.

There is even a window at the rear of the box truck camper conversion, from which Tegan can look outside while chilling on her couch bed.

The access door is super cute and matches perfectly the surrounding walls.

While there may not be a ton of space inside Marcel, Tegan managed to fit decent cabinets and shelves around the box truck conversion, so she can store her gear and food for longer trips.

Tegan found Marcel on Craiglist after months of searching.

She did all the build DIY, with a little help from friends. She wanted to learn how to do it all by herself.

After all her hard work, she and Marcel set off on new exciting adventures around the USA. You’ll find them anywhere with good mountain biking trails, wild swimming spots, deserts and mountains.

Check out Tegan’s Instagram account, Stormynorma, to keep up to date with her outdoorsy adventures and to see more of Marcel.

Need more inspiration for your van life kitchen? Check out 9 Campervan Kitchen Design Ideas for Van Life.

Jem’s Adventure Box Truck Camper Conversion

Jamie, Eric and Mayla the cat have refitted a Ford E350 box truck to travel the world together. The van used to be employed for a gutter and exterior business, but they snapped it up to make it into a home on wheels.

The van used to be employed for a gutter and exterior business, but they snapped it up to make it into a home on wheels.

Their box truck camper conversion interior design looks luxurious, thanks to their choice of components – they are all borrowed from home furnishing.

The galley of this box truck conversion looks like a regular home kitchen with a gas hob and oven, sleek surfaces and hidden-away fridges. The ceiling is simply stunning with its wooden slats.

Jamie and Eric even managed to squeeze a composting toilet in a separate mini room, so they can camp in the wild without a problem.

The door that separates the cab from the living space matches the wall panels around it and the couches turn into a double bed.

The rugs and paintings add the final touch, making this van a true home away from home.

There are four big solar panels on the roof to provide the couple and their furry child with enough power to stay gone for long periods of time.

We are so impressed with this box truck camper conversion. If you want to find out more and look at more pictures, have a peek at Jem’s Adventure Box Instagram profile.

Camping off grid? See the best solar generators for van life and Rving.

Luke And Sarah’s Box Truck Camper Conversion

Luke and Sarah opted for the DIY box truck conversion route, too. And what a tiny home they have built for themselves and their pooch!

Thanks to their clever use of space and the roomy interior offered by their 14ft Ford E350 from ’94, they have been able to fit both a permanent bed and couch inside their box truck camper conversion.

Shall we even mention the flat screen TV by the bed? Next to the bed, there’s a small cubicle with a composting toilet and a shower.

The kitchen of their box truck conversion has plenty of surface space and storage, as well as a regular hob, oven and refrigerator. The cabinets on the opposite side of the vehicle, where the couch is, match those of the kitchen.

Want to find out more about this box truck camper conversion? Have a look at Luke and Sarah’s Instagram account – Escaping The Midwest.

Betsy The Box Truck Camper Conversion

Betsy is possibly one of the cutest box truck camper conversions we could find – her exterior looks so charmingly retro, it’s hard not to turn around when you see her on the road.

The box truck conversion interior, with the leather and wooden details is simply stunning.

On the roof of the vehicle, there is a lovely sundeck made of wooden slats. The ladder that leads up to it looks solid and sleek, making a solarium session seem easy to organize.

In the back of the box truck conversion, the living space design is practical and modern.

The kitchen sink is huge and features a stunning industrial style tap. The regular oven and camper stove also doubles as surface space, thanks to the glass cover on top.

On the left-hand side of the box truck conversion, there is a decent size couch, big enough to have a nap on. The foam is thick and comfortable, so it will last a good amount of time.

The foam is thick and comfortable, so it will last a good amount of time.

The bed is right at the front of the vehicle. It’s a platform bed with storage space underneath. There is also a toilet (a Nature’s Head) and a shower in a separate cubicle. There is an outdoor shower stuffed away.

The lighting by the bed is incredibly clever, as it creates a lovely mood for reading, watching TV or Netflix, and relaxing. On the roof, there are 400W of solar power, which feed into the 400aH of batteries and a 2000W inverter.

Nick, the owner, has refitted Betsy, a Ford E-350 Boxtruck, all alone in Michigan. He is now travelling around the USA, looking for the perfect mid-sized city to settle down in, with his partner and puppy.

If you’d like to find out more about this box truck camper conversion or Nick’s travels, check out Betsy The Box Truck’s Instagram account.

Contravans Box Truck Camper Conversions

If you’d rather let a professional handle your box truck conversion interior, Contravans, based in Colorado, offer great conversion packages based around your needs.

A typical box truck conversion includes a platform bed with a memory foam mattress, a kitchen area (excluding a hob or oven), walls and ceiling with insulation, LED interior lighting, and lots of storage.

Additionally, each conversion comes with an auxiliary electrical system with batteries, solar panels, an inverter, and USB charging stations.

Going down the professional conversion path will save you a lot of time, research and work on your box truck camper conversions.

All you have to do is get in touch with the company, discuss your needs, agree on a floor plan, take your box truck camper over, and drive it to their HQ. Within a few weeks, you will be able to pick up your brand new conversion.

If you’d like to find out more about Contravans’ box van camper conversions, check out their website here.

Check out campervan conversion kits here.

Eric’s Ultimate DIY Budget Stealth Box Truck Conversion

If you’re on a tight budget, Eric’s story will inspire you. He bought this box truck for only $1,500 and refitted it DIY. The result is incredible.

He bought this box truck for only $1,500 and refitted it DIY. The result is incredible.

The truck still looks like a working van on the outside, to keep it extra stealth, but the interior turns it into a colorful, gipsy-style camper.

At the rear of the van, there are two couch benches, which turn into a small double bed. For eating, Eric carries a foldable table that he can use both inside and outside.

At the back of the left couch, there is a big flat screen TV.

Next to the couch, there’s a decent size galley with a regular sink, a fridge, a cooler, and a portable gas hob.

In front of the kitchenette, there’s a toilet cubicle with a composting toilet and space to shower.

Eric takes a portable shower with him on the road so he can have indoor and outdoor showers alike.

He also has plenty of storage spaces, such as cabinets and drawers.

Conclusion On Box Truck Camper Conversions

In conclusion, while box trucks don’t look extra cute to begin with, as you can see, you can totally transform them into a cozy home on wheels.

Meaning if you are considering a box truck for an RV conversion, there’s plenty of inspiration out there, which will help you shape one into the tiny house of your dreams.

Check out more van life content below!

Self-made pickup truck

Own child

Sergey Shakhmatov (Verkhny Ufaley, Chelyabinsk region), photo by the author

Hello, the editors of the magazine "Gruzovik Press". I am sending you a description and photos of my truck.

But first, a little background.

The first attempt to build a car was at the age of 15, when we, four friends, started building a car on the GAZ-69 type. But the company broke up, and everything that had been started, alas, had to be dismantled. Early 19In the 1980s, he began preparations for the production of a small four-seat coupe, not similar to the then existing industrial designs, but changed life circumstances forced him to abandon everything again. In the early 90s, he made a trailer for a car, which he managed to register. After some time, he began to manufacture furniture. The trailer was very useful for transporting material - sheets of laminated chipboard, which had to be sawn. Then the idea was born to build a small half-ton truck. nine0003

After some time, he began to manufacture furniture. The trailer was very useful for transporting material - sheets of laminated chipboard, which had to be sawn. Then the idea was born to build a small half-ton truck. nine0003

The standard size of a laminated chipboard sheet and determined the dimensions of the loading platform (2.50x1.85 m). The body turned out to be somewhat wide, but convenient for transporting furniture - roomy and low (loading height 750 mm). The supporting structure is a spinal-type frame, the main element of which is a large-section pipe. The spars of the bridges are also made of pipes structurally connected to the main triangle. The rear axle is a beam - a thick-walled pipe with flanges welded on the ends for mounting hubs taken from Moskvich-2141. Springs from IZH-Oda. Additionally, rubber buffers are installed. When installing the hub, the brake shield was deployed in such a way that the brake cylinder was at the bottom, and the handbrake cable was at the top, in more favorable conditions (souring of the parking brake cable is a “disease” of many cars). The spinal type of the frame made it possible to place the "spare tire" and the gas tank inside the wheelbase (2650 mm) high from the road surface. The "reserve" is attached with a hook with a nut on a special bracket. For ease of installation, a heel is made. A hatch is provided in the floor of the body for access to the gas tank (fuel gauge sensor, gas receiver, filler neck clamp). nine0003

The spinal type of the frame made it possible to place the "spare tire" and the gas tank inside the wheelbase (2650 mm) high from the road surface. The "reserve" is attached with a hook with a nut on a special bracket. For ease of installation, a heel is made. A hatch is provided in the floor of the body for access to the gas tank (fuel gauge sensor, gas receiver, filler neck clamp). nine0003

The tailgate only opens with clips. Front suspension - racks from the VAZ-2108 with reinforced springs. The rack and pinion steering is borrowed from the Moskvich-2141, but the tie rods are lengthened, since the front wheel track is 1600 mm. The VAZ-2101 engine is connected to the gearbox from the Audi 100 through an adapter plate. The splined part of the clutch disc has been redesigned. It should be noted that Audi has 14-inch wheel disks, and 13-inch ones are used on the car, so there is a noticeable loss in speed, but there is a gain in traction, which is more important for a truck. nine0003

In order not to increase the front overhang, the radiator had to be placed at an angle on the side. Wheel drive shafts are welded. Internal with CV joint from Audi, external from VAZ-2108. Moreover, they are cut off so that one (rod) enters the other (pipe) to a depth of 10 cm, which is safe in case of a rupture of the weld. The body of the VAZ-2101 (roof, pillars, doors, hood) was taken as the basis for the cabin. The back wall is waterproof plywood (10 mm) with built-in glass from GAZ-52. The floor of the cabin is in two levels, under the seats above, due to which the landing is almost vertical. Seats from Audi. The mechanism for tilting the backrest forward has been slightly improved. nine0003

Wheel drive shafts are welded. Internal with CV joint from Audi, external from VAZ-2108. Moreover, they are cut off so that one (rod) enters the other (pipe) to a depth of 10 cm, which is safe in case of a rupture of the weld. The body of the VAZ-2101 (roof, pillars, doors, hood) was taken as the basis for the cabin. The back wall is waterproof plywood (10 mm) with built-in glass from GAZ-52. The floor of the cabin is in two levels, under the seats above, due to which the landing is almost vertical. Seats from Audi. The mechanism for tilting the backrest forward has been slightly improved. nine0003

A storage box is located behind the backrest. The dashboard from the VAZ-2107 is enlarged downwards, where the central light switch, the ignition switch from the Moskvich-412, and the glove compartment are located. The instrument panel has been slightly changed - an ammeter is built in, control lamps of the direction indicator are spaced apart.

On the center console there is an emergency switch for the electric fan of the cooling system with a warning lamp (in case of failure of automatic activation), a clock, a cigarette lighter, two speakers. Two more speakers in the doors. The stove remained "native" (2101). With the volume of the cabin reduced by half, there is an excess of heat. The steering column switch (from Audi and the steering wheel) is very convenient. The battery is located under the floor of the left seat in a special box with a hatch, locked from the cab. A muffler is installed symmetrically to the battery relative to the frame (without a resonator). nine0003

Two more speakers in the doors. The stove remained "native" (2101). With the volume of the cabin reduced by half, there is an excess of heat. The steering column switch (from Audi and the steering wheel) is very convenient. The battery is located under the floor of the left seat in a special box with a hatch, locked from the cab. A muffler is installed symmetrically to the battery relative to the frame (without a resonator). nine0003

For 6000 km there was not a single structural failure (although our roads match the Dmitrovsky training ground). True, I had to replace the spring bushings and the right strut brace twice (the quality of the spare parts leaves much to be desired). Three years of operation have shown that the car is easy to maintain, unpretentious, comfortable, which was required.

In conclusion, I would like to touch on the topic of homemade registration. For the "homemade" this is a big problem, if not insoluble. Do government officials really not understand that by introducing bans, they simply kill in people the desire to create, invent, create - a constitutional right, by the way. And as for the accident rate on the roads, it’s not the “home-made” ones that increase the numbers of sad statistics, but our broken roads and those who simply ignore the traffic rules. And who put up his idea, going through dozens of options, decisions in his mind, and then turned it into reality, doing everything or almost everything with his own hands, shedding a hundred sweats at the same time, putting a particle of his soul, will not go out onto the road without giving an account of his responsibility, and even more so, he will never put his offspring, his child, under attack (in the literal and figurative sense) ...

And as for the accident rate on the roads, it’s not the “home-made” ones that increase the numbers of sad statistics, but our broken roads and those who simply ignore the traffic rules. And who put up his idea, going through dozens of options, decisions in his mind, and then turned it into reality, doing everything or almost everything with his own hands, shedding a hundred sweats at the same time, putting a particle of his soul, will not go out onto the road without giving an account of his responsibility, and even more so, he will never put his offspring, his child, under attack (in the literal and figurative sense) ...

Back to history. And now there are boys-dreamers. I saw how the eyes of the boys burn, greedily examining unusual equipment, when I was a participant in the second city review competition of old and home-made equipment in September 2004. There was a report on local TV and radio, an article in small circulation. And how nice it was with the words “our local Kulibin” to receive the first prize from the hands of the mayor of the city, who promised to make the review competition traditional, but the government changed, and the tradition did not work out. On hearing the phrase "folk art". Singing, dancing, theatre, art... All this, of course, is wonderful. But we should not forget about people of a technical mindset, and if the "techies" feel their relevance, then everyone will benefit from this. nine0003

On hearing the phrase "folk art". Singing, dancing, theatre, art... All this, of course, is wonderful. But we should not forget about people of a technical mindset, and if the "techies" feel their relevance, then everyone will benefit from this. nine0003

Please enable JavaScript to view the comments powered by Disqus.

Homemade trucks: from Russia with love

Useful information

Modern "Ant", assembled according to the drawings of the magazine "Modelist-Konstruktor".

Despite the two decades separating today from the rich Soviet past, the seeds of extraordinary, creative ideas still sprout in the field of modern capitalism and sometimes give good results. Homemade trucks have become a tradition for our country, because in the modern world a car and a driver are separated by the most complex engineering technology, electronics, and numerous and expensive tools. And the products of the Soviet automobile industry pushed the driver to modernize, although not always effective, but quite understandable design, practicality of the device, ease of modernization. nine0003

nine0003

Truck on the IZH engine: from the Volga and Moskvich-407 cars, it is proposed to take semi-elliptical springs, shortening them first, and make the rear suspension spring, independent.

Recall at least the now famous products of the Tula Machine Building under the unpretentious name "Ant". One type of this wheeled vehicle suggests the manufacture of a flatbed truck based on a scooter. By the way, the first "Ant" (not TG-200) was assembled in 1966 by hand-made Ivchenko and Molchanov. The Java-350 engine located behind the rear axle made it possible to lower the center of gravity and, together with the wagon layout, to make the body more stable on the road. With a power of 14.3 hp. (4500 rpm), this home-made mini-truck developed up to 70 km / h, and its diagrams were published in the magazine "Modelist-Konstruktor" for the 70th year. nine0003

Indeed, salvaged mopeds and motorcycles are the basis for most of these crafts. This is probably due to the fact that the design of a moped is the easiest to adapt to domestic needs: you don’t need to mess around with a complex transmission - you attach a body and go. Homemade mini trucks are not going to be admired as a work of art (although this also happens), but because this type of transport is a great helper in the household.

Homemade mini trucks are not going to be admired as a work of art (although this also happens), but because this type of transport is a great helper in the household.

General principle

Most often, the base of a homemade mini-truck consists of a welded tubular frame, in the central part of which is the engine. The motor can be removed from any old motorcycle or moped. The cabin is made from parts of old cars. Since all transmission parts are usually borrowed from other cars, the levers and control pedals are usually placed on the right side of the cab.

Wheels are most often combined (processed machine wheels, with motorcycle or even cart wheels). Masters of such home-made steering designs recommend using motorcycle and scooter tires. Wheels are selected depending on the driving conditions. Homogeneous and dual wheels are suitable for a smooth, unproblematic road. While wide profile motorcycle tires are suitable for off-road driving or just difficult sections of the road. nine0003

nine0003

Homemade truck is driven by a walk-behind tractor engine without a silencer, the body is made of lumber, the wheels are low-pressure tires. Cons design — front-wheel drive and heavy steel wheels.

The body of a homemade truck is easiest to assemble from lumber: they are inexpensive, they do not require any special equipment during installation. Of course, the body can also be removed from a tractor or from any other vehicle, but its weight and dimensions must be taken into account - such a body needs to be finalized. A good welding machine opens up wide opportunities, the presence of which makes it possible to weld the body frame in the garage. nine0003

Frame for a self-made truck

In the general flow of frame structures offered by modern Kulibins, frames that break and are monolithic can be distinguished. The idea of a breaking frame pursues two goals at once - obtaining high mobility and combining elements of different cars in one design. So the frame consists of two parts fastened to each other by a hinge. The latter most often is a universal joint removed from another truck. However, such a mount can move in any direction, and its degrees of freedom must first be limited to “right-left” by welding lugs to the edges of the gimbal cross. nine0003

So the frame consists of two parts fastened to each other by a hinge. The latter most often is a universal joint removed from another truck. However, such a mount can move in any direction, and its degrees of freedom must first be limited to “right-left” by welding lugs to the edges of the gimbal cross. nine0003

For greater maintainability and reliability, it is recommended to look for ready-made car frames, for example, from GAZ-51, and more often than other passenger cars in the drawings and diagrams, you can see the converted Moskvich-412. The diagram below shows a drawing of a homemade truck from Ryazan. For obvious reasons, you can’t attribute it to the “mini” category, but the principle of maximizing the use of factory nodes should be noted. Such equipment is a real constructor, on the basis of which you can build trucks even in your own garage. On this car, not only the frame was taken from the GAZ-51, but also the suspension from the same car. nine0003

A craftsman from Ryazan cut out the middle cross member from the frame of a GAZ-51 car. The cardan and the rear axle were shortened, but the front axle was not changed.

The cardan and the rear axle were shortened, but the front axle was not changed.

Frame shortened by 90 cm by removing the middle part, together with one of the cross members. To strengthen the welding, overlays from sheets 4 mm thick were used. Such a modification was necessary in order to avoid reworking the hitch and finding a point for attaching the springs. The disadvantage of the approach can be considered the need to shorten the driveshaft, rear axle and axle shafts. The author also had to go for a reduction in the gauge: the “stockings” from the crankcase were shortened by 88 mm (along the way, new “factory” grooves had to be applied to them and separated from the crankcase). nine0003

The main material for self-made frames are channels with numbers from 6.5P to 10P, cylindrical and square pipes 40x40, 80x80, etc. It is recommended to strengthen the welding site with additional overlays, especially in places where elements like springs are fastened. Less significant details are strengthened with ordinary metal corners, bars, etc. V. Mikhailov and the Chelyabinsk region took the frame from a mobile pumping station as the basis of his truck (scheme 1, scheme 2, scheme 3). At the same time, the master reminds that the frame width is calculated from the width of the axles, the diameter and the angle of rotation of the front wheels, and that when choosing the frame length, it is more logical to start from the base (the distance between the axles), and not vice versa. nine0003

V. Mikhailov and the Chelyabinsk region took the frame from a mobile pumping station as the basis of his truck (scheme 1, scheme 2, scheme 3). At the same time, the master reminds that the frame width is calculated from the width of the axles, the diameter and the angle of rotation of the front wheels, and that when choosing the frame length, it is more logical to start from the base (the distance between the axles), and not vice versa. nine0003

This video shows a homemade truck from Canada. The original cabin and frame are assembled from improvised materials (thin steel, pipes and corners). But no less interesting is the location of the Volkswagen engine, which stood transversely on its native chassis.

Engine

The advantage of the latter is the possibility of lowering the center of gravity and low vibrations, which becomes important when it comes to a heavy body mounted on a light chassis. Engines from typical power plants (UD-4, UD-2, etc.) are popular. It is sometimes easier to get diesels and gasoline engines from stations than to recover junk, but power units from cars are also found in homemade schemes. nine0003

Engines from typical power plants (UD-4, UD-2, etc.) are popular. It is sometimes easier to get diesels and gasoline engines from stations than to recover junk, but power units from cars are also found in homemade schemes. nine0003

It's hard to imagine that a homemade truck would require good dynamics and acceleration. Torque selection is critical, however some high speed motors will be able to be used with a reduction gear. At low speeds, four-stroke diesels demonstrate a good N˙m value. And on the diagrams you can often see ZAZ power units, but more importantly, they can also often be found on really working equipment. The durability of these motors, equipped with a good, by the standards of our reality, atmospheric cooling system, is worthy of special mention. nine0003

Homemade truck from Camobdia.

Tractor engines from the T-16, T-25, etc. have proven themselves well. Motors like the D-21A1 can be adapted for domestic needs: power - 25 hp, maximum speed - 1800. True, a regular starter from these engines can do not pull the Russian cold weather, so the native starter is often changed to a starter from the T-40. Additionally, the motor can be improved by adding a cardboard filter to it, and given the dimensions, it is better to place it behind the cab. With the GAZ-51 box, engines from the T-16 can be connected with a native clutch, although in this case you will need to use a sheet metal adapter with holes for mounting and a shaft. nine0003

Additionally, the motor can be improved by adding a cardboard filter to it, and given the dimensions, it is better to place it behind the cab. With the GAZ-51 box, engines from the T-16 can be connected with a native clutch, although in this case you will need to use a sheet metal adapter with holes for mounting and a shaft. nine0003

GAZ-53 rear axle connection with Mazda 2.0 l engine.

In the regions of the Far North, the simplest design of motorized sleds has proven itself, which is an engine from the Druzhba-5 saw or similar (scheme 1, scheme 2, scheme 3), connected to a caterpillar chassis. The principle of use is to make the saw turn not the chain, but the tracks. In this case, the motor itself is located in front, on skis fastened to a bicycle fork, and the driver, along with the load, is located above the tracks. Power of 4 hp enough to disperse 80-kilogram sledges up to 60 km / h in the snow. nine0003

Transmission

Wheels on self-made trucks are most often not installed native, so a regular box sometimes cannot provide the necessary effort. The way out of this situation may be to use a rigid box from GAZ (models 53 and 51) along with a low-power engine T-16, M-72, etc. In this case, the truck drawing usually includes an adapter from a metal plate. The need for such a design arises from the difference in the size of the input shaft of the gearbox and the crankshaft of the power unit. nine0003

The way out of this situation may be to use a rigid box from GAZ (models 53 and 51) along with a low-power engine T-16, M-72, etc. In this case, the truck drawing usually includes an adapter from a metal plate. The need for such a design arises from the difference in the size of the input shaft of the gearbox and the crankshaft of the power unit. nine0003

Mounted systems are easiest to use homemade or hydraulic, and at the same time it becomes necessary to include a power take-off in the transmission. The selection box can be shared by agricultural machinery or a recycled all-terrain vehicle. It is problematic to completely redo the bridges, but by shortening the axle shafts and “stockings”, you can change the dimensions of the base and the size of the track. Seats for axle shafts and bearings are easy to move to another point in the frame, but this procedure must be accompanied by strengthening the welding site. nine0003

Designer's platform - clean chassis MAN CAT.

Engineering

The most logical place to start looking for parts is with the axles and the engine.