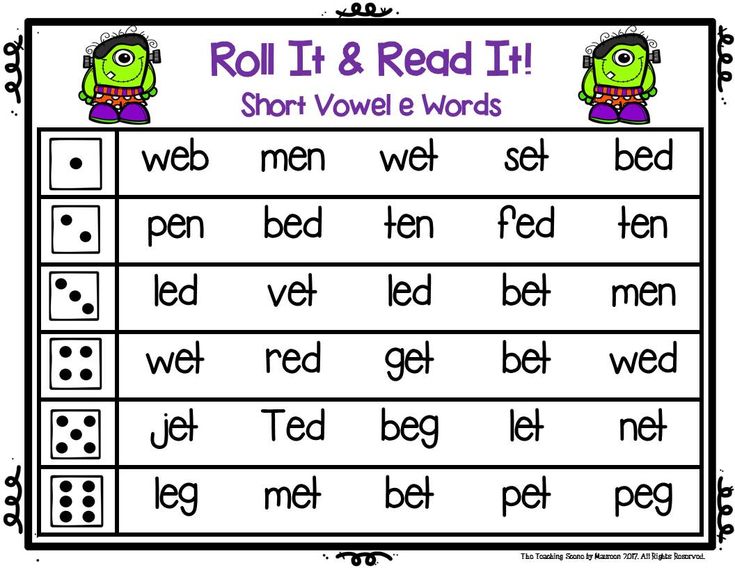

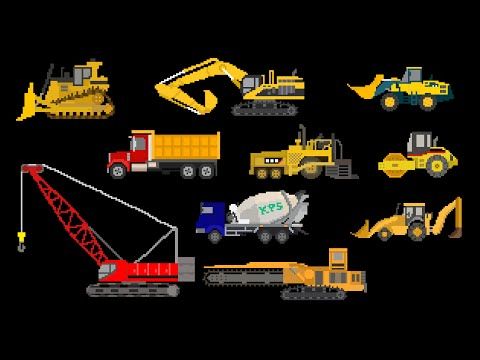

Construction site trucks

19 Different Types of Construction Vehicles

Be it excavation, dumping, or lifting, construction work includes moving heavy loads. It is not humanly possible to lift tons of weight without the help of any heavy machinery and vehicles. Construction vehicles are essential for all types of construction jobs, regardless of the size and scale. Whether it is the construction of a home building, or a large scale civil or commercial project, construction vehicles are a necessity.

Contents

- Types of Construction Vehicle

- 1. Bulldozers

- 2. Front Loaders

- 3. Dump Trucks

- 4. Backhoes

- 5. Grader

- 6. Trenchers

- 7. Cranes

- 8. Loaders

- 9. Crawler Dozers

- 10. Compactors

- 11. Excavators

- 12. Forklifts

- 13. Conveyors

- 14. Concrete Mixer Truck

As mentioned earlier, there’s a lot that needs to be done in the construction industry. With that being said, each of these tasks requires a different type of construction vehicle. There are many types of construction vehicles and almost all are used at some point at a construction site. Different types of construction trucks have been listed down below:

Bulldozer is the most common, most widely known, and the most-reliable type of construction vehicle. It is also the strongest among all other types. It wouldn’t be wrong to say that a bulldozer is basically a tractor with a huge blade fitted at the front. The metal blade which is characteristic of a bulldozer is powerful enough to drive a massive magnitude of sand, soil, debris, etc.

Bulldozers have an exceptional grip to the ground. They can be easily mobilized even on a patchy terrain. Bulldozers have wide tracks that are arranged over a vast area, distributing the weight of the gigantic construction vehicles. As a result, the pressure applied is greatly decreased.

Bulldozers have a torque divider that transforms the engine power into significant dragging capability, that allows them to tow heavy tanks with great ease. Bulldozers are used to remove obstacles, debris, bushes, trees, and to clear roads. They can also be employed to dig trenches, in military operations, and farming works.

Bulldozers are used to remove obstacles, debris, bushes, trees, and to clear roads. They can also be employed to dig trenches, in military operations, and farming works.

A front loader is an earth moving equipment, that is also known as scoop loader, bucket loader, front-end loader, or front loader. Front loaders are similar to a bulldozer, only further away from the ground. They have huge wheels that make them suitable to be used in extremely rough terrains. They have moveable arm with a wide square bucket which is used to move material around. The bucket may be permanently attached or it may be removable. Sometimes, the bucket is replaced with other tools such as hydraulically operated bucket or forks.

The primary purpose of front loaders is moving dirt. They are used in construction sites and when roads are being fixed. Front loaders are used for the transport of building materials such as bricks, metal bars, pipes, and digging tools. They are also used for snow removal.

They are also used for snow removal.

A dump truck is one of the most popular types of construction vehicles. Dump trucks are primarily used to dump debris away from the construction site. They can also be used to bring additional construction material to the construction site.

There are many types of dump trucks that are available.

Off-Road Dump TrucksThey are also known as articulated trucks. They are huge construction vehicles that are used for mining operations where significant amounts of aggregate have to be hauled. They are ideal to be used off-road, that is, on rough terrain.

Transfer Dump TrucksTransfer dump trucks are a type of trucks that are pulled by a separate trailer. The trailer has a movable cargo container. It greatly increases the load capacity of the vehicle without affecting the maneuverability.

Side Dump TrucksThey are the fastest dump trucks for unloading huge amounts of debris. They are preferred on sites where there is a lot of space to maneuver because of their length. They tilt on the side for dumping and have a lower risk of tipping over.

They are preferred on sites where there is a lot of space to maneuver because of their length. They tilt on the side for dumping and have a lower risk of tipping over.

The standard dump truck is the most commonly used dump truck at the construction sites. They cannot be used on soft soils. They have great maneuverability.

4. BackhoesBackhoes is another type of construction vehicle that is used to move the earth. Backhoes can be mounted on a regular tractor or a front loader. They are used at the construction sites to dig trenches and ditches for laying cables, pipes, and foundations. It can excavate dirt and also move snow.

Backhoes can travel to rough terrains where other construction vehicles may not be able to travel. They can be used to clean the construction site, dig deep-rooted tree roots, and trees. They can pat down any loose soil. Moreover, backhoes can also be used to plant trees and dig post holes.

Graders, also known as road graders or motor graders, are heavy equipment construction vehicle that has a long blade. The primary purpose of a grader is to remove any small amounts of dirt and create flat surfaces. Graders are usually used for the construction of roads and construction and maintenance of gravel roads and dirt roads.

Graders are also used to prepare the base court of paved roads for the creation of a wide, flat surface on which the asphalt is placed. They are also used to set native soil foundation pads before the construction of large buildings.

6. TrenchersTrenchers are a very versatile construction vehicle that can be used for a variety of purposes. Its flexibility makes it popular. Trenchers can be used for digging trenches, laying pipes, installing drainage, and for the preparation of trench warfare.

There are different types of trenchers, which are:

Chain TrenchersChain trenchers consist of a digging chain and a track trencher. They are used to cut ground and to form deep and narrow trenches.

They are used to cut ground and to form deep and narrow trenches.

Wheel trenchers consist of a toothed metal wheel. They are used to cut pavements during road maintenance. Construction companies use wheel trenchers to gain access to under road utilities.

Micro TrenchersMicro trenchers are used when construction work has to be carried out in urban areas. The cutting wheel in micro trenchers cut micro trenches, rather than huge trenches that would disrupt the urban routine.

7. CranesCranes are one of the most useful construction vehicles. They are composed of pulleys and cables that allow them to lower and lift loads beyond the capabilities of humans. They do not just help in lowering and lifting loads, they also move material horizontally. Construction companies use cranes at the construction sites to aid the movement of heavy materials, which human workers cannot move about.

Cranes can be static or mobile. Mobile cranes have large wheels to provide stability and support to the crane while it is raised high, holding a heavy load. Tower cranes are a commonly used type of crane in the construction of tall buildings.

8. LoadersAs the name indicates, loaders are used to load materials. Loaders are used at construction sites to not just load but also move construction materials around. They are used to load and move materials like dirt, snow, asphalt, demolition debris, gravel, recycled materials, and rocks.

Loaders may be wheeled or tracked. Wheeled loaders are more like mobile shovels that aid in the transfer of material from stockpiles on the ground to trucks and transport them around the construction site. Loaders may be of different types including front loaders, bucket loaders, skid-steer loaders, payloaders, and scoop loaders. Every type of loader has a different use.

The assembly of a loader can vary. They can either be permanently mounted or they can have a removable attachment. The bucket can be augmented as well.

They can either be permanently mounted or they can have a removable attachment. The bucket can be augmented as well.

Crawler dozers are one of the most powerful construction vehicles. Crawler dozers are tracked vehicles that have excellent stability. They have a variety of blades mounted on its front that help in moving material. They are very often used in pioneer work, such as laying new roadways or to remove overburden during mining. Smaller crawler dozers are used as grading tractors or for using automated grade controls for the establishment of complex contours.

10. CompactorsIf you do not have adequate soil compaction, there could be an erosion of the foundation, pipe breaks, and leakages, and slab cracks. These problems can result in structural failure and an unnecessary increase in maintenance costs. The better the foundation, the better is the building. A compactor is, therefore, a very important construction vehicle that is used for soil compaction. No matter how big or small a construction project is, a compactor is a necessary construction vehicle.

A compactor is, therefore, a very important construction vehicle that is used for soil compaction. No matter how big or small a construction project is, a compactor is a necessary construction vehicle.

Compactors are of different types. There is baler-wrapper compactor that is used to make compact bales, a trash compactor that is used to reduce the volume of the trash, vibrating plate compactor that is used in narrow areas hard to maneuver, rammers that are used to make trenches, smooth rollers that are used during road constructions, and many more. Smooth rollers are the most commonly used type of compactors.

11. ExcavatorsExcavation is the primary activity that takes place at every construction site. The excavation is so large-scale that heavy excavation equipment is needed. Excavators are one of the most valuable construction vehicles.

An excavator consists of a bucket, boom, dipper, and a cab that is located on a rotating platform (house). The house sits on the top of tracked or wheeled undercarriage. They come in many sizes; the smaller ones are called compact excavators or mini excavators.

The house sits on the top of tracked or wheeled undercarriage. They come in many sizes; the smaller ones are called compact excavators or mini excavators.

Excavators are used for the digging holes, trenches, and foundations. presence of hydraulic hammers makes them more efficient and effective than any of the other excavation equipment. They are used in almost all industries, including mining, construction, forestry, demolition, material handling, dredging rivers, or simply to lift heavy objects.

12. ForkliftsForklifts are a very powerful construction vehicle. They are used to move heavy loads around the construction site or in a warehouse. They aid in lifting and transporting objects that a human cannot move. It makes forklifts an indispensable vehicle at all job sites.

There are many types of forklifts, each having a different load capacity. The types range from simple pallet jack to industrial telehandler. The difference in all types is the maximum weight they can lift.

The operator cannot just raise or lower the forks or blades, but they can also be tilted to compensate for loads that have a tendency to angle the blades towards the ground and increase the risk of slipping.

13. ConveyorsConveyors are machines that are used to convey materials from one spot to the other. They can be used to move materials of any shape, size, and weight. Conveyor systems are used in numerous industries including agriculture, automotive, mining, electronic, aerospace, pharmaceutical, food processing, print finishing, bottling and canning, and packaging.

You must be wondering why we are considering a conveyor as a construction vehicle. Sometimes, the shaft of the conveyor is supported by wheels which allow the movement of the shaft, around a construction site. Wheeled conveyors can be seen at construction sites commonly to move bulky stones and bricks from one point to the other.

14. Concrete Mixer TruckA mixer truck is a construction vehicle that combines cement, sand or gravel, and water homogenously to form concrete. A mixer truck consists of a revolving drum mounted on the truck that mixes all components together.

A mixer truck consists of a revolving drum mounted on the truck that mixes all components together.

When smaller quantities of cement are needed at a construction n site, a portable concrete mixer (concrete mixer truck) is often used. It provides the workers enough time to use the concrete before it gets hard.

Construction vehicles are necessary for any construction project. Despite the presence of numerous laborers at the site, it is not possible for human workers to do everything by hand. The use of construction vehicles and construction equipment does not just speed up the construction process but also helps workers by making their jobs less laborious and strenuous.

24 Types of Construction Vehicles and How They Are Used

Equipment

By: BigRentz on September 7, 2022

Construction vehicles allow crews to perform all sorts of tasks more quickly and efficiently. From digging trenches in the field to hauling construction materials like aggregate or stone, different types of construction vehicles help you do it. You can choose from highly specialized units designed for a specific task or select a single versatile vehicle that can perform multiple functions.

From digging trenches in the field to hauling construction materials like aggregate or stone, different types of construction vehicles help you do it. You can choose from highly specialized units designed for a specific task or select a single versatile vehicle that can perform multiple functions.

In this post, we identify the different types of common construction trucks, what tasks they perform, how they work, and their key features.

1. Articulated Haulers

Articulated haulers function as heavy-duty dump trucks that move large amounts of materials around or off construction sites. Articulated haulers differ from other types of dump trucks because they feature a pivot joint, like articulated trucks, that gives them more mobility. They make tighter turns because the pivot joint allows their back wheels to follow where the front wheels go. Most articulated trucks have all-wheel drive, giving them the ability to safely maneuver on all types of rough terrain.

- Key feature: Articulated haulers can carry massive loads while making tighter turns and can remain stable on all sorts of terrain.

- Where they are commonly found: The ability of articulated haulers to navigate muddy and rocky conditions makes them popular in the mining industry. You may also find them on construction jobs, hauling materials to the site or debris from the site.

2. Asphalt Pavers

Asphalt pavers lay asphalt for paving projects like roadways, parking lots, and walkways. Pavers distribute and compact layers of asphalt, often followed by a roller to smooth the pavement. Some asphalt pavers attach to tractors or dump trucks, while others are self-propelled. Asphalt pavers come in several different varieties with differing horsepower, so consider the size, surface, and timeframe of your paving job when deciding which machine to use.

- Key feature: Asphalt pavers utilize a screed unit that levels your material uniformly as well as flattens and compresses.

- Where they are commonly found: Workers use asphalt pavers on all sorts of paving jobs, ranging from mountain roads and commercial parking lots to sidewalks and golf cart paths.

- Types of asphalt pavers:

- Tracked pavers: Track-mounted pavers have a rubber track on each side, allowing the machine to propel itself. Ideal for softer surfaces, tracked pavers offer greater stability in sandy or soggy conditions and work well on new paving projects and mountainside applications.

- Wheeled pavers: Since they don’t offer the same traction as tracked pavers, wheeled pavers work better on existing road surfaces. They move faster and deliver better efficiency than tracked pavers, making them the better choice for paving long stretches of asphalt or for night work that may have time constraints.

3. Backhoe Loaders

While mostly used for excavation, backhoe loaders can perform a variety of tasks in the landscaping, construction, and agricultural sectors. Backhoes feature both a front loader to plow materials and a backhoe with a digging bucket (or other attachment), along with stabilizer legs to prevent the vehicle from tipping over. Backhoe loaders vary in size, horsepower, bucket capacity, and digging depth, so make sure to consider all your worksite requirements when choosing a backhoe.

Backhoe loaders vary in size, horsepower, bucket capacity, and digging depth, so make sure to consider all your worksite requirements when choosing a backhoe.

- Key feature: The versatile backhoe can perform a wide range of tasks on all kinds of terrain working in conjunction with its three main parts: the tractor, loader, and backhoe.

- Where they are commonly found: Worksites of all types can find a use for the backhoe loader. The construction industry may use them for breaking up pavement, small demolition tasks, or cleaning up a worksite. The agriculture and landscaping industries may use them to uproot trees, dig ponds or trenches, and move heavy loads of dirt or rocks.

- Types of attachments:

- Augers: Corkscrew-shaped bits allow backhoes to drill holes of varying sizes.

- Compactors: Powerful compacting attachments can tamp down soil on excavations or drive in sheeting in retaining walls.

- Hammers: Demolition and earth preparation projects can use hammers (also known as breakers) to break up rock, soil, and other materials.

- Snow handlers: Attachments such as blowers, buckets, pushers, angle brooms, snow blades, and V-blades allow backhoes to perform heavy-duty snow removal jobs.

- Rippers: Rippers use a strong curved tool to cut through thick materials such as ice, rock, hard ground, and asphalt.

4. Boom Lifts

A type of aerial lift, boom lifts raise workers and materials at construction sites, providing access to hard-to-reach areas. The lifts consist of a platform or bucket on a hydraulic arm attached to a moveable base on the ground. Boom lifts allow workers to access scaffolding, painting, piping, utilities, building exteriors, and tree projects. Because they can extend higher and farther than other types of lifts (such as scissor lifts), boom lifts make an ideal construction vehicle for projects requiring maximum reach.

- Key features: Able to maneuver both vertically and horizontally, boom lifts can extend people or materials up to 210 vertical feet and 115 horizontal feet.

- Where they are commonly found: You can find boom lifts in many indoor and outdoor environments, including warehouses, construction sites, farms, and orchards.

- Types of boom lifts:

- Articulating boom lift: Featuring arms with multiple joints—giving it the nickname “knuckle lift”—the articulating boom lift can maneuver around obstacles in tight spaces.

- Telescopic boom lift: With an arm that extends and contracts in a straight line, this boom can reach the farthest.

- Bucket truck: Designed for outdoor use, this heavy-duty vehicle features a railed aerial platform attached to a hydraulic crane.

5. Bulldozers

One of the most popular types of construction trucks, bulldozers assist with pushing, digging, excavating, and leveling materials at a construction site. You can recognize these heavy-duty earthmovers by their giant blade on front used to push large amounts of soil, debris, and other materials. Bulldozers have multiple blade types that serve varying purposes and handle different materials. Some dozers also come with additional implements, such as a ripper in the rear that helps break down rocks or tough soil.

You can recognize these heavy-duty earthmovers by their giant blade on front used to push large amounts of soil, debris, and other materials. Bulldozers have multiple blade types that serve varying purposes and handle different materials. Some dozers also come with additional implements, such as a ripper in the rear that helps break down rocks or tough soil.

- Key feature: Bulldozers use a large front blade to push massive amounts of materials over a variety of terrain types.

- Where they are commonly found: You can find bulldozers pushing materials like snow, gravel, and soil on roadways, construction sites, mining operations, and more.

- Types of bulldozers:

- Crawler bulldozer: Crawler dozers feature tracks rather than wheels, which give them superior traction on rough terrain.

- Wheel bulldozer: Also known as a tire bulldozer, wheel dozers offer enhanced maneuverability and greater ability to move on soft surfaces.

- Mini bulldozer: These compact machines offer better speed, handling, and versatility than some of the bigger options.

6. Cranes

Used to lift and move heavy materials, cranes are a staple of construction projects across the country. Cranes come in a variety of types—wheeled and tracked, static and mobile, water and land—that can help you perform all sorts of tasks. Whether you need to stack goods in a warehouse, carry large volumes of building materials, or lift cargo off ships, you can find a specialized crane to suit your needs.

- Key feature: Cranes can move heavy loads to great heights—up to 265 feet, or more if attached to a building.

- Where they are commonly found: You can find cranes at a wide range of job sites, including warehouses, industrial workstations, off-road terrain, offshore oil rigs, commercial ports, mining projects, and construction projects ranging from skyscraper erection to bridge building.

- Types of cranes:

- Mobile cranes: Mounted on crawlers or tires, mobile cranes provide greater mobility than fixed cranes. These types of cranes can navigate around job sites (and sometimes even on the road) while carrying large amounts of weight, making them popular additions to many construction projects.

- Fixed cranes: Fixed cranes cannot move and usually require on-site assembly, but can generally lift heavier loads and reach greater heights than their mobile counterparts.

7. Cold Planers

Cold planers grind and remove asphalt or concrete, preparing paved surfaces for new pavement. From fixing slab cracks and broken curbs to road and sidewalk repair, cold planers break up old asphalt or concrete, mill the material, and move it to a container for later recycling. These machines require some skill to use, as operators must set them at the right depth and alignment. Some cold planers attach to tractors or skid steers, while others operate as self-contained motorized vehicles.

- Key feature: Cold planers can help the repair of damaged hard surfaces by both breaking down old pavement and recycling it for future use.

- Where they are commonly found: Road crews and construction companies may use cold planers on roads, parking lots, and other paved surfaces.

8. Combine Harvesters

A useful multipurpose agricultural machine, combine harvesters simplify the process of harvesting crops like wheat and corn. This large, complex farm instrument not only gathers and cuts crops but also separates grains from stalks in a process known as threshing. Besides enabling the harvesting of wide tracts of crops, combines also have removable heads to conveniently harvest different types of crops. Farms of varying kinds and sizes can take advantage of the labor-saving power of the combine harvester.

- Key feature: Combine harvesters streamline the harvesting, winnowing, and threshing process into a single machine, which improves productivity, increases crop yield, and decreases cost.

- Where they are commonly found: Farms of varying types and sizes may use combine harvesters, including those that grow rice, corn, wheat, sunflower, pulses, barley, flax and soybeans.

9. Concrete Mixer Trucks

As the name tells you, concrete mixer trucks are primarily used to mix concrete. A hydraulic motor spins a large drum where cement, water, and other aggregate materials like sand and gravel mix together. The concrete then exits the truck through a chute for use in a wide variety of commercial and industrial applications.

- Key feature: The constantly spinning drum of a mixer truck enables workers to have a continuous supply of concrete at the ready.

- Where they are commonly found: You can find concrete mixer trucks almost everywhere: residential construction jobs, commercial building sites, civil engineering enterprises, and roadway projects.

10. Double Drum Rollers

Heavy-duty surface and soil compaction machines, double drum rollers flatten surfaces in preparation for construction projects. Whether you need to smooth out uneven ground before paving or flatten a foundation to make building easier, a drum roller can help.

Whether you need to smooth out uneven ground before paving or flatten a foundation to make building easier, a drum roller can help.

While a single drum roller has a steel drum in front and wheels in the back, a double drum roller has one drum in front and one in back. Although this decreases its maneuverability somewhat, it produces improved power, efficiency, and coverage. If you’re looking to smooth asphalt, of all types of compactors to choose from, the double drum will help you do so quickly and effectively.

- Key feature: Double drum rollers feature two steel drums which enable the machine to flatten a variety of surfaces quickly and efficiently.

- Where they are commonly found: You may find double drum rollers on road and parking lot paving projects, or anywhere with a large and gradual surface like asphalt.

- Types of drum rollers:

- Grid rollers: Thanks to a network of steel bars on the drum that create grid-like patterns, grid rollers offer high-contact pressure with little kneading.

Usually pulled behind a tractor or other heavy machine, grid rollers work best on well-graded coarse soils and weathered rocks.

Usually pulled behind a tractor or other heavy machine, grid rollers work best on well-graded coarse soils and weathered rocks. - Pneumatic rollers: A large ride-along vehicle, the pneumatic roller has several rows of rubber tires that provide uniform pressure throughout the width of the tires.

- Sheepsfoot: The drum on the sheepsfoot roller features rectangular-shaped lugs (or “feet”) which work well for compacting soil, silty clay, and wet clay in road construction projects. You can also increase the drum weight by filling it with water or damp sand, providing a more efficient compacting job.

- Smooth wheeled or static rollers: Smooth rollers come in both single drum (or three-wheeled) and double drum (or tandem). Single drum rollers can generally work in tighter spaces while double drum rollers offer efficient smoothing of larger, flatter surfaces.

- Vibratory rollers: Similar to smooth-wheeled rollers, vibratory rollers add a vibrating component that helps fill in the empty spaces to better compact soil, asphalt, and concrete deep under the surface.

- Grid rollers: Thanks to a network of steel bars on the drum that create grid-like patterns, grid rollers offer high-contact pressure with little kneading.

11. Dump Trucks

Dump trucks have deep, open beds that make carrying and transporting large volumes of loose material easy. Crews use dump trucks for all kinds of hauling tasks: bringing materials to a construction site, removing debris and other waste, and moving an endless variety of loose matter including soil, gravel, sand, scrap metal, grain, and coal. True to their name, dump trucks make it easy to dump loads out of the bed.

Dump trucks come in a range of sizes and payload capacities for a variety of projects. If a standard dump truck won’t do the trick, you can choose from other types, like a transfer dump truck that has a separate trailer or a side dump truck that can dump its load from the side.

- Key feature: Dump trucks feature deep beds that make them ideal for hauling and dumping large volumes of material.

- Where they are commonly found: You will see dump trucks wherever large volumes of matter need to be moved: mining operations, construction sites, road work, landscaping jobs, agricultural applications, and more.

12. Excavators

One of the more popular earthmoving vehicles at any construction site, excavators make it possible to lift and move heavy loads. With its rotating cab, movable tracks, an arm, and a variety of attachments, excavators can perform a variety of other functions. In addition to moving heavy materials, this versatile construction equipment can grade uneven terrain, drill deep holes, break down walls, and much more.

- Key feature: This indispensable piece of earthmoving equipment uses its bucket and arm to excavate material and utilizes movable tracks allowing it to perform on a variety of terrain types.

- Where they are commonly found: Excavators perform a huge variety of construction and industrial functions, including mining, landscaping, demolition, roadwork, underwater tasks, civil engineering projects, pool digging, residential work, forestry and more.

- Types of excavators:

- Crawler excavators: With two large tracks rather than wheels, crawler excavators have more stability on uneven terrain, making them ideal for mining operations and heavy-duty construction jobs.

- Wheeled excavators: Similar in size and appearance to crawlers, wheeled excavators run on wheels instead of tracks. The wheels make them faster and easier to maneuver on concrete, asphalt, and other flat surfaces common in urban projects.

- Dragline excavators: A heavy-duty machine used for large-scale projects, dragline excavators use a hoist rope system to raise and lower the bucket while the dragline pulls the bucket toward the operator.

- Suction excavators: Also known as vacuum excavators, suction excavators feature suction pipes that carry away dirt and debris at up to 200 miles per hour. Suction excavators can reduce the chance of damage by up to 50%, making it perfect for delicate underground applications.

- Skid steer excavators: Unlike regular excavators, skid steers feature booms and buckets that face away from the operator. This orientation allows the attachments to reach over the cab instead of around it, which makes these excavators useful for residential work and other tight spots.

- Long reach excavators: Popular for demolition projects and hard-to-reach locations, long reach excavators feature arms that can extend up to 100 feet horizontally.

- Mini excavators: If you need a machine that can maneuver around small indoor spaces or parking lots, these compact excavators may fit the bill. Often offering limited tail-swing, mini excavators can negotiate tighter turns and avoid contact with obstacles.

- Crawler excavators: With two large tracks rather than wheels, crawler excavators have more stability on uneven terrain, making them ideal for mining operations and heavy-duty construction jobs.

13. Feller Bunchers

A machine that revolutionized the lumber industry, feller bunchers can cut down 4,000 trees in a single day. The feller uses a high-speed disk saw to cut trees and then a hydraulic arm to pick them up and stack them gently for transport. The machine’s tracks provide excellent traction without damaging the forest floor. Operators can control the feller buncher with a single joystick.

- Key feature: Feller bunchers use their grapple and blade to efficiently cut and bunch large trees with one machine.

- Where they are commonly found: You will mostly find these specialized vehicles on construction and logging sites.

14. Forklifts

Forklifts use a forked attachment to lift heavy materials and carry them over short distances. Commonly found both in construction work and warehouse settings, these powered industrial trucks excel at moving palletized loads and raising them overhead. Forklifts vary by maximum lifting capacity, arm reach length, and tire type, which makes it easy to find a unit that meets your specific material-handling needs.

- Key feature: Forklifts feature a double-pronged attachment to lift and transport heavy loads.

- Where they are commonly found: You can find forklifts in indoor settings like storage facilities and warehouses with polished floors and tight aisles. You will also see them in a wide range of outdoor settings, from construction sites and lumberyards to loading docks and rough-terrain industrial applications.

- Types of forklifts:

- Warehouse forklift: Warehouse forklifts work well for loading and unloading packaged products in warehouses, factories, and distribution centers. They come with either cushioned tires, which work best on smooth indoor surfaces, or pneumatic tires, which can handle more uneven surfaces.

- Side loader: A kind of warehouse forklift, side loaders allow users to stand in a sideways compartment while the machine unloads objects. You may find side loaders particularly useful for handling long loads like timber and pipes.

- Counterbalance forklift: Counterbalance, or counterweight, forklifts ensure a proper weight distribution to prevent the forklift from tipping over when lifting heavy loads.

- Heavy-duty forklift: These jumbo-sized trucks use hydraulic levelers to lift particularly heavy loads—up to 100,000 pounds.

- Walkie stacker: Walkie stackers have a smaller frame and tighter turning radius than standard forklifts, making them ideal in areas with limited space.

- Order picker: A type of walkie stacker, order pickers shine in customer order warehouses and storage facilities because they can pick individual pieces of inventory without having to bring down full pallets.

15. Forwarders

Heavy pieces of logging equipment, forwarders do the work of collecting and transporting felled trees and logs. The articulated machines feature an enclosed operator cab, a long bed for wood, and a hydraulic arm with a claw-like attachment (called a grapple) that can grasp multiple trees at once.

- Key feature: Forwarders are forestry vehicles that pick up, load, and transport logs by themselves.

- Where they are commonly found: You will likely find these specialized vehicles in forestry and logging operations.

16. Manlifts

Also known as personnel lifts or personal lifts, single manlifts elevate a single operator to an aerial workspace. Manlifts feature retractable outrigger legs and drive tracks to stabilize the foundation on any terrain. When choosing a manlift model, consider the size and maximum reach needed for your job, and also the power source available at your site. Indoor single manlifts can operate using an electrical socket, while outdoor lifts can use batteries, gas, or diesel fuel.

Manlifts feature retractable outrigger legs and drive tracks to stabilize the foundation on any terrain. When choosing a manlift model, consider the size and maximum reach needed for your job, and also the power source available at your site. Indoor single manlifts can operate using an electrical socket, while outdoor lifts can use batteries, gas, or diesel fuel.

- Key feature: Manlifts allow a single worker to safely perform tasks in elevated spaces inaccessible by ladders or other means.

- Where they are commonly found: You will see manlifts in warehouses, on construction sites, in building maintenance operations, in home renovation projects, and even at photography shoots.

- Types of manlifts:

- Self-propelled manlift: The smallest of the group, this compact lift can raise one person and a set of tools 15-20 feet in the air.

- Push-around manlifts: Ideal for fitting in tight spots like between rafters or next to HVAC units, push-around manlifts can reach heights of 15-50 feet.

- Atrium (belt) manlifts: Also known as compact crawler lifts, these heavy-duty lifts work best in outdoor construction jobs. The unit’s extended neck can reach heights of over 34 feet and maneuver around tall obstacles like trees and power lines.

17. Motor Graders

Heavy equipment vehicles with a long blade, motor graders excel at flattening and leveling surfaces. The machines roll and mix materials, while breaking down dirt for better compaction.

The grader’s rubber tires allow operators to move on all types of surfaces at the construction site, as well as drive on the road at speeds of up to 30 miles per hour. All-wheel drive graders enable crews to work on slopes and soft terrain.

- Key feature: The large blade of a motor grader makes it ideal for leveling surfaces.

- Where they are commonly found: You often find motor graders on roadwork projects, but you may also find them doing duty on other construction, agricultural, and mining jobs.

- Types of grader attachments:

- Front blades: Straight and angled front blades come in a variety of sizes, allowing the grader to effectively perform snow removal, grading, land-leveling, or dozing activities.

- Fenders: Fenders help protect your grader by preventing the build-up of mud, snow, and debris.

- Hydraulic broom: This front-mounted attachment allows your grader to clear loose rocks or debris from roads.

- Push block: Push blocks protect motor graders when operators use them to push other machines. This dual-purpose attachment can also serve as a counterweight for the rear ripper.

- Scarifiers: Scarifiers help break up compacted soil, asphalt, and other tough surfaces.

18. Scissor Lifts

A scissor lift features a rising platform that elevates workers and materials to higher areas. Unlike some other construction lifts, scissor lifts can only move up and down and have a relatively limited maximum height. However, scissor lifts can carry multiple workers at once and offer a steady, enclosed platform that enables workers to perform precision tasks at higher elevations. Scissor lifts come in a variety of sizes, applications, and fuel types.

However, scissor lifts can carry multiple workers at once and offer a steady, enclosed platform that enables workers to perform precision tasks at higher elevations. Scissor lifts come in a variety of sizes, applications, and fuel types.

- Key feature: Scissor lifts feature a larger aerial platform and a criss-cross design that can add stability, allowing workers to complete precise tasks at an elevated height.

- Where they are commonly found: You can find scissor lifts in both indoor and outdoor projects, including construction, building maintenance, window installation, sign hanging, and window cleaning. You may also find them in retail environments and warehouses.

- Types of scissor lifts:

- Hydraulic: Hand-operated or engine-driven hydraulic systems power this type of scissor lift. Relatively easy to operate, hydraulic scissor lifts don’t require a high level of user training and make a simple solution for your lifting needs.

- Diesel: Among the most commonly used lifts on construction sites, diesel lifts can reach a maximum height of 30 to 60 feet. However, because they emit noise and fumes, they are better suited to outdoor rather than indoor use.

- Electric: Quieter, cleaner, and smaller than diesel lifts, electric scissor lifts make a great choice for enclosed spaces.

- Rough-terrain: Designed exclusively for outdoor conditions, rough-terrain scissor lifts come with a high weight capacity, heavy duty tires, and additional safety mechanisms like fall restraints. This makes them ideal for outdoor work sites that may have uneven ground surfaces and inclement weather.

- Pneumatic: A more eco-friendly option than traditional lifts, pneumatic scissor lifts require only air and do not emit fumes or other hazardous materials into the environment.

- Hydraulic: Hand-operated or engine-driven hydraulic systems power this type of scissor lift. Relatively easy to operate, hydraulic scissor lifts don’t require a high level of user training and make a simple solution for your lifting needs.

19. Skidders

Used in logging operations, skidders drag logs from where they fall in a forest to a collection point called a landing. If operated properly, skidders will economically transport logs while minimizing the damage to soil and vegetation. Skidders come in both tracked and wheeled varieties, which have different speeds and slope-handling abilities. Thanks to an articulated joint in the middle, wheeled skidders can maneuver around standing trees.

If operated properly, skidders will economically transport logs while minimizing the damage to soil and vegetation. Skidders come in both tracked and wheeled varieties, which have different speeds and slope-handling abilities. Thanks to an articulated joint in the middle, wheeled skidders can maneuver around standing trees.

- Key feature: This important piece of logging equipment pulls cut trees out of a forest.

- Where they are commonly found: You will most often see skidders in forestry and logging operations.

- Types of skidders:

- Cable skidders: Cable skidders pull logs towards them with steel cables with looped attachments called chokers. This enables the vehicles to stay on the trails, which limits damage to the soil and root systems.

- Grapple skidders: Grapple skidders lift groups of logs by grabbing them by the end. They can offer greater speed and maneuverability.

20. Skid Steer Loaders

A compact, maneuverable vehicle often used for digging, skid steer loaders can perform an impressive range of tasks. A variety of attachment options allows this multipurpose machine to do everything from excavating, trenching, and drilling to clearing snow, wood chipping, and pallet lifting. Also known as skid loaders or wheel loaders, skid steers come in models with either four wheels or two tracks. The machine’s name comes from the fact that drivers can operate one side of wheels independently, making the other side skid or drag across the ground.

- Key feature: The skid steer loader’s wide range of attachment options allow this compact vehicle to perform a variety of construction, landscaping, warehouse, and residential tasks.

- Where they are commonly found: Skid steer loaders perform a variety of useful services on construction sites, such as pavement milling, mixing cement, and moving building materials.

You can also find skid steers on farms, in warehouses, at landscaping projects, or in residential areas.

You can also find skid steers on farms, in warehouses, at landscaping projects, or in residential areas. - Types of skid steers:

- Small-frame: Lighter and more maneuverable, small-frame skid steers perform well in tight spaces.

- Medium frame: Ideal for completing heavier tasks in small spaces, the medium-frame skid steers have a higher horsepower than small-frame models.

- Large frame: Construction companies can employ large skid steers to perform extensive excavation and demolition work while maneuvering around a job site.

21. Telehandlers

Telehandlers, or telescopic handlers, can carry heavy materials and place them with precision. Sometimes considered a combination between a crane and a forklift, telehandlers offer the pallet-lifting prongs of a forklift and the increased range of motion of a crane.

The telescopic booms on a telehandler can move not only up and down or left and right, but also diagonally. They also extend and retract to move around obstacles. Telehandlers have optional attachments, allowing operators to move different types of loads on a single worksite.

They also extend and retract to move around obstacles. Telehandlers have optional attachments, allowing operators to move different types of loads on a single worksite.

- Key feature: Telehandlers offer an unmatched combination of heavy-duty lifting power, flexibility, maneuverability, and stability on uneven surfaces to carry materials.

- Where they are commonly found: You will see telehandlers on construction and industrial projects, where the vehicles can lift loads of different materials while offering stability even on rough terrain. You may also see the machines lifting and placing palletized loads in warehouses.

- Types of attachments:

- Buckets: Bucket attachments scoop up bulky loads and loose materials such as sand, soil, or gravel.

- Pallet forks: Two-pronged forklift carriages allow telehandlers to perform the same load-carrying functions as a forklift.

- Crane jibs: Enabling telehandlers to function more like a crane, crane jibs provide hooks that help operators carry materials over and around obstacles.

- Work cages: These aerial platforms allow telehandlers to lift workers to higher locations.

22. Tractors

An iconic agricultural vehicle, tractors perform a variety of tasks on the farm, such as plowing, harvesting, fertilizing, and spraying. Their influence has spread to a variety of other worksites, where they can help clear land, dig foundations, do heavy lifting, drill holes, and remove snow. Tractors often have large, wide tires that distribute the weight of the vehicle, preventing it from crushing the surface below. A variety of useful implements can attach to the rear of the tractor, including buckets, forks, mowers, box scrapers, or wood chippers.

- Key feature: Tractors make hard jobs easier by delivering high power at low speeds.

- Where they are commonly found: While tractors are almost synonymous with farms, you can also find them performing all sorts of jobs in the mining and construction industries, as well as landscaping and construction.

- Types of tractors:

- Utility tractors: These versatile vehicles can get it done—whether you want to clear snow, bale hay, or work livestock.

- Compact tractors: Small farmers, landscapers, and DIY homeowners may find these small units just their size.

- Row crop tractors: Row crop tractors perform the work of growing and harvesting specific types of crops.

23. Trenchers

As the name suggests, trenchers create smooth, straight trenches as they dig through the earth. These heavy-duty earthmoving machines feature a metal chain with steel teeth, allowing them to tear into densely packed soil and heavy tree root systems. Although both excavators and trenchers dig ditches as they move, trenchers create a cleaner trench with less backfill, allowing you to work faster. Trenchers come in a variety of models with different specifications and applications.

Trenchers come in a variety of models with different specifications and applications.

- Key feature: Trenchers move massive amounts of earth while leaving behind clean trenches with flat bottoms and smooth sides.

- Where they are commonly found: All sorts of construction tasks employ trenchers, including cutting pavement or concrete, creating drainage for sewage and water runoff, cutting trenches for electrical cables and telecommunications wires, digging spaces for water and sewage pipes, snipping tree roots, and even lighter digging work for home improvement and landscaping projects.

- Types of trenchers:

- Chain trenchers: With their chainsaw-like design, chain trenchers use a digging chain or belt to cut into the ground. They make a good option for making deep, narrow trenches for utility companies.

- Wheel trenchers: Also called rockwheels, wheel trenchers have a toothed metal wheel that you can use for hard or soft soils.

Wheel trenchers work well in areas with many rock formations.

Wheel trenchers work well in areas with many rock formations. - Micro trenchers: Micro trenchers dig trenches with much smaller dimensions than traditional trenches, ranging from 0.5 to 2 inches wide and around 2 feet in depth.

24. Wheel Tractor Scrapers

The tractor scraper consists of a tractor with an engine combined with a scraper unit. As the tractor moves forward, the scraper blade cuts into the earth and fills its trailer bowl with material. Scrapers specialize in moving or removing soil, gravel, or other material from the ground surface. They also help in other earthmoving tasks including excavation, leveling, loading, hauling, and dumping.

- Key feature: A tractor scraper combines a tractor with a scraper, allowing you to efficiently move and remove material from the ground surface.

- Where they are commonly found: You can find scraper tractors in construction, road building, mining, agriculture, and forestry.

- Types of scrapers:

- Single-engine wheeled scrapers: The most common scrapers generally need a bulldozer to push them forward in order to load their bowls.

- Dual-engine wheeled scrapers: These powerful, self-loading scrapers feature one engine in the front of the vehicle and one in the trailer.

- Elevating scrapers: These scrapers can remove, mix, and homogenize soil, enabling them to complete fine finished grading.

- Pull-type scrapers: If you have a tractor that you already use with a range of attachments, you might find a pull-style scraper convenient and economical.

Conclusion

If you’re looking to rent a certain construction vehicle, check out BigRentz. We provide a variety of vehicles you may rent such as forklifts, boom lifts, excavators, or skid steer loaders. Choosing a construction vehicle is no easy task and it may vary depending on the type of environment you’re working in, the job task, and what you need the equipment for. Be sure to consider the pros and cons of each type of equipment.

Be sure to consider the pros and cons of each type of equipment.

Related Posts

Get the latest from the Think Big Blog delivered to your inbox.

Featured

Explore Equipment Topics

Equipment Rental Guides

Download any of our free rental guides and learn how to pick the right equipment to fit your project needs.

Construction trucks | Renault Trucks

Construction cycle trucks work intensively in extreme off-road conditions. Cars are operated on dusty, muddy and steep slopes. Renault Trucks offers reliable, comfortable construction trucks.

Table of content

- Increase volume with your construction equipment

- Maximize the work done by your construction trucks

- Choose a construction truck with a body that is easy to build

- Monitor how your fleet is being used and reduce fuel consumption

- Reduce maintenance costs

- Tailor your financing plan to your earthworks

Increase volumes with your construction machinery

Moving sand, earth or gravel is the first step in starting construction. Renault Trucks C and K series trucks will increase the volume of your daily transportation due to the maximum load capacity and reinforced construction chassis.

Renault Trucks C and K series trucks will increase the volume of your daily transportation due to the maximum load capacity and reinforced construction chassis.

Renault Trucks C is the lightest 8x4 model on the market, weighing just 9,200 kg. Its carrying capacity can reach 22.8 tons.

If you often work in particularly harsh environments, you may want to choose the XTREM version of the Renault Trucks K. Its load capacity has been increased to 34 tons, and the total load capacity is 100 tons for the 6x4 holder and up to 120 tons for the 6x4 tractor. Renault Trucks C and K can carry a mass of 13 tons per rear axle.

Maximize the amount of work your construction trucks can do

During development, our vehicles are rigorously tested to ensure impeccable durability on construction sites. The high ground clearance ensures a particularly wide approach angle, which avoids grounding and possible damage to the chassis.

° The Renault C and K trucks boast some of the best entry angles, and the K model has 15 inches of ground clearance under the axle and 20 inches under the tank.

For each vehicle, the chassis stringers can be reinforced in different places depending on the body to ensure structural stability. To avoid clogging the engine, Renault Trucks K is equipped with a cyclonic pre-filter to remove dust from the air.

Any loading or vehicle problems on the construction site can result in loss of time and work efficiency. To reduce this risk and improve driver safety, the cab of the trucks has excellent visibility. Drivers can also keep an eye on their load with ease thanks to the side stand, which can be safely reached using rooftop handles.

Renault C and K trucks are equipped with several assistance systems to assist drivers on construction sites:

- Hand throttle to increase engine power on unstable ground

- Hill Start Assist

- Electric and automatic parking brake

- Optidriver automatic transmission with off-road mode for easy shifting on construction sites

- Extended mode with extra slow gear for driving on construction sites with heavy loads

- Differential motor lockable with thumbturn for better access

- Optibrake, the most powerful engine brake on the market

Renault Trucks are great on construction sites and on the open road. Their powerful engines and driving performance ensure high commercial speed during transport, while avoiding excess consumption, which increases your profitability.

Their powerful engines and driving performance ensure high commercial speed during transport, while avoiding excess consumption, which increases your profitability.

Choose a construction truck with a body that is easy to build

Our vehicles are designed to help your coachbuilder of choice easily and quickly build a body. You can choose the exact wheelbase you need based on your activity, and we also offer several different fittings to make it easy for bodybuilders to mount their equipment.

Vehicle chassis also have prefabricated fittings for installing equipment, running electrical cables or creating a cab interface.

Several areas under the chassis are left empty, so you can add different equipment according to the selected body design. We do all this work in close cooperation with body builders to make their job easier and shorten the time it takes to build your vehicles.

Monitor how your fleet is being used and reduce its fuel consumption

As you may have noticed, fuel consumption at construction sites can increase quite quickly. Most often this happens because the use of vehicles is not optimized. By choosing Optifleet, a fleet management solution developed by Renault Trucks, you can get detailed information about the fuel consumption of your vehicles and understand the factors that contribute to this. High consumption can be caused by driving style, excessive engine idling, or high power take-off. Optifleet also alerts you when you exceed a threshold that you set. The EcoScore module identifies areas where your drivers need to improve and offers a specific program designed for work on construction sites.

Most often this happens because the use of vehicles is not optimized. By choosing Optifleet, a fleet management solution developed by Renault Trucks, you can get detailed information about the fuel consumption of your vehicles and understand the factors that contribute to this. High consumption can be caused by driving style, excessive engine idling, or high power take-off. Optifleet also alerts you when you exceed a threshold that you set. The EcoScore module identifies areas where your drivers need to improve and offers a specific program designed for work on construction sites.

Reduce Maintenance Costs

During construction work, the strength and reliability of vehicles and parts are tested. To help you avoid unnecessary expenses and plan your vehicle maintenance, Renault Trucks offers a variety of customized maintenance packages. These plans are transparent, quickly implemented and do not require long-term commitments. Bills and duration of service are also determined in advance. All maintenance work is carried out at authorized service stations by specialists who have received special training in the technologies and products used by Renault Trucks. We only use genuine parts to keep your vehicles running smoothly.

All maintenance work is carried out at authorized service stations by specialists who have received special training in the technologies and products used by Renault Trucks. We only use genuine parts to keep your vehicles running smoothly.

To reduce costs, when a used or damaged part needs to be replaced, Renault Trucks offers a standard exchange service. Instead of using a brand new part, we refurbish and refurbish parts according to a strict manufacturing process and test every item before selling. The quality and performance of the remanufactured part meets the same requirements as new parts and is guaranteed for two years. Over 2,000 parts can be used for this service, which is more economical than new parts, so you can save money without sacrificing quality.

Tailor your financing plan to your earthworks

To help you finance your vehicles, Renault Trucks offers a variety of solutions that are ideal for your construction business. Our formulas take into account the time of work and the specifics of the activity. For example, we know that the annual mileage in the construction industry is usually quite short, so we make sure to tailor the duration of the financing plan to optimize operating costs. Your consultant will support you every step of the way in choosing the best formula.

For example, we know that the annual mileage in the construction industry is usually quite short, so we make sure to tailor the duration of the financing plan to optimize operating costs. Your consultant will support you every step of the way in choosing the best formula.

FOR MORE INFORMATION, CONTACT US!

Like it? Share it!

Tony's truck and construction vehicles

Description of

If your child loves cars, trucks and cars in general, this app is the right one to download.

Tony's truck is very busy at the construction site. Everyone needs his help - Dan the excavator, Carl the bulldozer, Hugo and Amos the cranes, Ben the asphalt paver, Ron the concrete truck, and, of course, the loader brothers Max and Rex. Where will Tony go first?

The app has been designed for children from 1 to 4 years old so that your child can use the app on their own and the navigation is clear to them. There are no ads in the application, parental control is applied for all links.

There are no ads in the application, parental control is applied for all links.

Two screens are available for free, the rest can be purchased in the app itself.

For more information about the application, visit http://www.tonythetruck.com. If you have any suggestions for improvement, please provide feedback or write us a few words at [email protected].

Version 1.3.2

- optimizations for iOS 8.2

Ratings and reviews

ratings: 6

Excellent!

The child loves it! Developers! Update the app! UPDATE THE APP!!!!!!!!!!!!!!!!!!!!!!!

Pregnant

Why remat 4 years?????

Return the money.

The child is delighted with your application, for this you get 5 stars, but I (mother) are already angry, I have paid for in-app purchases more than once and have not received them. And the child is already hysterical that all the rest of the cars are blocked. Please correct the situation or return the money!

Yomio's developer has not disclosed to Apple its privacy policy or data practices. Detailed information is available in the developer's privacy policy.

N/A

Developer will be required to provide privacy information when submitting the next app update.

Information

- Provider

- Yomio s.r.o.

- Size

- 116.4 MB

- Category

- Education

- Age

- 4+, for children 0-5 years old

- Copyright

- © 2014 Yomio s.

Learn more