A fire engine

Ukraine war round-up: A drone attack and a fire engine delivery

Published

Related Topics

- Russia-Ukraine war

Image source, EPA

Image caption,Ukrainian firefighters at the site of a drone attack in Kyiv on Monday

By Patrick Jackson

BBC News, London

A week after Russia's mass missile strikes on Ukraine in retaliation for the attack on the Crimea bridge, the Russians struck Kyiv from the air again, but this time using "kamikaze" drones.

At least four people, including a pregnant woman, were killed in the capital despite the attempts of security forces to down the slow-moving unmanned aircraft, which explode on impact. Four others also died in the northern region of Sumy in strikes reportedly targeting energy infrastructure.

Calls went up in Ukraine and among EU leaders for sanctions to be slapped on Iran which continues to deny supplying Russia with the drones, in the face of all the evidence. We have this explainer on "kamikaze" drones.

Despite Russian President Vladimir Putin's announcement last week that there was no need for further large-scale attacks for now, his military reported missile strikes on Ukraine's energy systems and military command facilities on Sunday.

And fighting raged in Donetsk, the eastern region where Russian-backed separatists and Russian troops are battling Ukrainian forces in a conflict stretching back years before Mr Putin launched his invasion in February.

In his nightly address on Sunday, Ukrainian President Volodymyr Zelensky said "extremely heavy fighting" continued around the towns of Soledar and Bakhmut, where "the occupiers threw everyone they could" against the Ukrainian defenders.

In a rare moment of good news, Ukraine and Russia announced they had carried out a mass prisoner exchange: each side released 110 detainees.-1.jpg)

Unusually, all of the Ukrainians freed are women, including 37 who surrendered at the Azovstal steel works in Mariupol. They were swapped mainly for sailors from crews of Russian merchant ships detained since the start of the war, but also a number of soldiers.

Cursed 100 times over

Image caption,Bakhmut is within reach of Russian artillery

Bakhmut reverberates to the sound of constant shelling, day and night, and it has been that way for weeks, the BBC's Jonathan Beale reports from the city.

Most of its 70,000 citizens have already fled and those who remain are mostly the elderly, living without running water or electricity.

"People are exhausted," says Olena, nearly 70, as she waits in a queue to be evacuated. Life has become too hard, she says, having to cook food on an open fire and fetch buckets of water.

"I curse the one who started this war," she says. "I curse him 100 times."

'One big prison camp'

For Russia to have any chance of advancing in Donetsk, it must replenish its forces after the bruising it received in the first months of the invasion.

Its controversial mobilisation of reservists - for a war still officially described as a "special military operation" - will play a part in that. Meanwhile the capital, Moscow, ended its mobilisation drive on Monday saying it had reached its quota of draftees.

Sergey is one of those former Russian soldiers who faced being called up again for a fight he likens to a war against Russians themselves and he has fled the draft, seeking refuge over the border in Georgia, then Turkey.

Hear him describe how he managed to get away and the emotional wrench of being separated from his homeland, which today he calls "one big prison camp".

This video can not be played

To play this video you need to enable JavaScript in your browser.

Media caption,Watch: One Russian's exhausting ordeal to escape conscription

If the actual war in Ukraine hangs in the balance then on the internet, it is a very one-sided affair, the BBC's Paul Adams reports from Kyiv.

Teams of social media volunteers work around the clock for Ukraine's defence ministry, reacting within hours to news from around the country, producing punchy videos, often set to music, for the ministry's audiences at home and abroad.

French President Emmanuel Macron's decision to supply Caesar self-propelled guns was greeted with a video featuring the Paris skyline and the sound of Serge Gainsbourg and Jane Birkin's breathless Je T'aime Moi Non Plus, plus the guns in action of course.

Image source, Defense of Ukraine

Image caption,Ukraine's plea for more French Caesar howitzers - in a humorous romantic video

Their most successful video, released in August after several mysterious attacks on Russian targets in annexed Crimea, mocked Russians for going on holiday on the peninsula and was set to the Bananarama song Cruel Summer.

Fire engines for the war zone

"It was a fantastic and humbling experience and will stay with me for the rest of my life. "

"

Shrewsbury firefighter Adam Matthews is speaking after returning from an epic road trip with 40 or so colleagues to deliver British fire engines and equipment for emergency services in Ukraine.

Two engines were among 10 vehicles taken on the 2,400-km (1,500-mile) journey to a drop-off point on the Ukrainian border.

Image source, Adam Matthews

Image caption,The convoy included 35 firefighters from across the UK

Throughout their journey through France, Germany and Poland, the team stayed at fire stations, gyms and exhibition centres.

"The hospitality throughout the whole trip was fantastic from those that hosted us," Mr Matthews recalls.

- Russia-Ukraine war

- Kyiv

- Russia

- Ukraine

Fire Apparatus Design: A Step-By-Step Guide

Overview

As a fire department considers adding a new fire truck to its fleet, it can be overwhelming to review and research all the possible configurations, combinations and components.

Pierce Manufacturing is ready to help.

Below, we outline the critical decisions that must be considered in the fire truck design and development process, outlining everything from basic definitions to complex configurations and component possibilities.

This page will review:

- How to determine your department goals

- Common fire truck definitions

- Types of apparatus

- Types of fire truck chassis

- How to choose the right suspension system

- Choosing the right engine

- How to select fire truck doors

- Electrical system considerations

- Safety Systems

- Firefighting foam system selection

- A review of fire truck body compartmentation

- Final design considerations

Download this Guide

The purchase process for fire apparatus involves many steps and many mission-critical decisions. Use this free guide as a tool to help your fire department and municipality understand the steps needed to build a fire truck.

Understand the Goals Of Your Fire Department

Before doing any research into truck types, configurations and components, it is important to have a clear understanding of the immediate and long-long term goals of the fire department.

- The main mission of the fire truck. Will a new truck be the workhorse of the department, responding to every call, or is it meeting an existing gap in coverage? These considerations can help a fire department determine the best truck type, chassis and components to include in a truck specification.

- Current fleet needs. Whether you are replacing an existing apparatus in your fleet or considering a new type of truck, it’s important to evaluate your current fleet of trucks and determine how a new truck fits into your fleet.

- Service area requirements. Each community has unique needs and the fire trucks that service the community must match these needs.

Are there narrow streets or tall structures? Big highway systems or densely populated areas? Rural areas with limited water supply and resources? A fire truck must be designed to match the service areas.

Are there narrow streets or tall structures? Big highway systems or densely populated areas? Rural areas with limited water supply and resources? A fire truck must be designed to match the service areas.

- Geographic terrain. There are many types of fire trucks, each designed to manage specific tasks and, in some cases, specific terrain. Does your service area have flat terrain, or rough, variable terrain? Hills or valleys? Will your vehicle need to go off road? The geographic region can make a big difference in vehicle weight considerations, engine size, horsepower and more.

- Climate. The climate in a region may have an impact on the types of components a fire department plans to use on a new fire truck. In fact, environmental factors may motivate a department to consider specific features, like blacked-out components, e-coat to help prevent deicing agent or salt-water deterioration or more advanced HVAC systems.

How Do You Choose the Right Apparatus and Chassis?

Every detail in the purchase of a fire truck matters. Therefore, understanding the mission of the truck will help your organization make an informed decision.

Therefore, understanding the mission of the truck will help your organization make an informed decision.

At Pierce Manufacturing, our team often considers this simple statement—will it fit?

- The needs of your fleet?

- The needs of your community and service area?

- The firefighters?

- The tools that are required for your mission?

- The space you have in your fire station? (height, length and width)

- Your budget?

The type of apparatus your department requires will drive the chassis you choose, which will affect your gross vehicle weight rating, which will, in turn, influence your powertrain and horsepower considerations. Ultimately, this will determine your payload capacity and the equipment and personnel that can be onboard

It's exactly why working with an experienced fire truck manufacturer to walk through the fire truck design process is so helpful.

Balancing your budget as well as all the critical elements and knowing what to look for to match the mission of a fire truck can seem overwhelming without the right guidance and support.

Learn more about the support Pierce can offer before, during and after the purchase of a fire truck.

Common Fire Truck Apparatus Definitions

Before a fire truck purchasing committee initiates research, it can be helpful to have a basic understanding of the key terms often used to describe fire trucks in the ordering process. Here is a brief overview.

NFPA standards for National Fire Protection Association, which delivers information and knowledge through more than 300 consensus codes and standards, research, training, education, outreach and advocacy.

Gross Vehicle Weight Rating (GVWR) is defined by NFPA 1901 as “the final-stage manufacturer’s specified maximum load-carrying capacity of a single vehicle.”

Curb Weight is the total overall weight of a vehicle alone, with no equipment or personnel on board. It is defined by NFPA 1901 as ‘the total weight of the complete vehicle less the payload. ”

”

Payload capacity is the total weight of all of the cargo, personnel and equipment on board a fire apparatus. The payload capacity is calculated by subtracting curb weight from a fire truck’s gross vehicle weight. Payload Capacity = GVWR – Curb Weight.

Gross Axle Weight Rating (GAWR) is defined by NFPA 1901 as “the final stage manufacturer’s specified maximum load-carrying capacity of an axle system, as measured at the tire-ground interfaces.”

Horsepower is the unit of measure for power and is often understood as the rate at which work can be completed.

Drivetrain is the interaction of several parts working together that when combined with the power, thrust a vehicle into motion. The drivetrain usually consists of the transmission, driveshaft, differential, axles and wheels.

Powertrain, on the other hand, can be understood as the elements of the drivetrain combined with the source of propulsion (diesel or electric engine) and the axles to put a vehicle into motion.

Angle of approach is defined by NFPA 1901as “the smallest angle made between the road surface and a line drawn from the front point of ground contact of the front tire to any projection of the apparatus in front of the front axle.”

Angle of departure is defined by NFPA 1901 as “the smallest angle made between the road surface and a line drawn from the rear point of ground contact of the rear tire to any projection of the apparatus behind the rear axle.”

Tip Load Capacity is used for aerial apparatus and refers to the maximum weight the aerial device can hold at the tip without tipping over the apparatus.

Why do these definitions matter, you may wonder? It is the perfect way to frame up a discussion of the types of available apparatus, chassis and beyond.

Type of Apparatus

The right type of apparatus is often the subject of early conversations when a new fire truck is being considered.

Fire trucks can also be classified by type and function according to The NFPA 1901 Standard, Standard for Automotive Fire Apparatus, and the National Wildfire Coordinating Group (NWCG) Standards for Wildland Fire Resource Typing.

To view more about this type of classification and why it exists, read our helpful blog post: Types of Fire Trucks: An Overview and Comparison.

Here is a brief overview of each type of fire truck apparatus:

Pumper Apparatus

A pumper apparatus, often referred to as a traditional fire engine, is a truck specifically designed to transport and pump water.

The National Fire Protection Association (NFPA) states that a pumper is “A fire apparatus with a permanently mounted fire pump of at least 750 gpm (3000 L/min) capacity, 300 gallon water tank, and hose body whose primary purpose is to combat structural and associated fires.”

Regarding equipment storage, NFPA requirements also note that pumpers must have a minimum of 40 cubic feet of enclosed weather-resistant compartmentation.

Pierce Manufacturing has several pumper fire truck configurations available to customers, from heavy-duty rescue pumpers to high-flow industrial pumpers, mini pumpers and more.

Aerial Apparatus

An aerial apparatus is often referred to as a tower, ladder or tiller fire truck and can include a platform as well.

According to NFPA requirements, an aerial apparatus must be equipped with an aerial ladder, elevating platform, or water tower as well as:

- A minimum of 115 ft of ground ladders, including one (1) attic ladder, two (2) straight ladders with folding roof hooks and two (2) extension ladders.

- A minimum of 40 cubic feet of enclosed weather-resistant compartmentation.

In addition, section 8.9.3 outlines an extensive list of minor equipment that must be included on every aerial apparatus before it is put into service, including the number of axes, pike poles, crowbars, SCBAs, wrenches, shovels and more.

Learn more about aerial fire trucks on our informational page here.

Rescue Apparatus

As its name suggests, a rescue fire apparatus is typically outfitted and used for rescue operations.

Rescue fire trucks are often equipped to match the designed rescue type, be it hazardous material mitigation, urban search and rescue, fire ground support, or water rescue, to name a few.

Rescue fire trucks can be classified further as either a walk-in rescue, where there is enclosed interior space or a non-walk-in rescue, consisting of body compartment storage throughout.

Compare the different types of rescue apparatus here.

Tanker Apparatus

A tanker apparatus or water tender is a specialized apparatus designed specifically to transport water to an emergency.

According to NFPA standards, a tanker truck must be equipped with a water tank(s) that meets NFPA 1901 Chapter 18 guidelines and provides a minimum water capacity of 1000 gallons. Some of the guidelines of a water tanker include detailed specifications in regard to construction, tank cleanout, tank-to-pump intake, tank-to-pump flow rate, filling and venting and overflow precautions.

Learn more about tanker apparatus now.

Pierce Ultimate Configuration Apparatus (PUC)

The Pierce Ultimate Configuration (PUC™) water pump is a unique design that minimizes the space required for the pump and pump controls, thereby increasing the maneuverability of the vehicle and improving the maintenance accessibility.

The PUC is available on pumpers, rescue pumpers, tankers and aerials.

Read our blog to learn more: Pierce Ultimate Configuration: 8 Key Benefits for Fire Departments.

Quint Apparatus

A quint fire truck is an apparatus that combines the equipment of a ladder truck and the water-pumping capabilities of a fire engine. A quint truck features five key elements to carry out firefighting functions:

- Water tank with a capacity of at least 300 gallons

- Water pump with a capacity of at least 1000 gallons per minute (gpm)

- Aerial device

- Fire hose

- At least 85 feet of ground ladders

A quint fire truck is a multifunctional tool offering the capabilities of a pumper and ladder truck, providing immediate support at the scene of an emergency.

Learn more about quint fire trucks here: Is a Quint Fire Truck Right for Your Department?

Fire Truck Environmentally-Focused and Alternative Power Technology

Only recently has the discussion of environmentally-focused technology been a critical factor for fire departments in the fire truck design and purchasing process. As a department considers its short and long-term energy goals, determining whether the inclusion of alternative power technology should be considered is now a big point of discussion.

Idle Reduction Technology

When a vehicle's engine is not being used to move, idle reduction technology steps in to offer environmental and cost-saving benefits. Idle reduction technology can shut off the engine while maintaining consistent power to perform other functions, like the use of accessories and scene lighting. Pierce® Idle Reduction Technology (IRT) pairs automatic diesel engine controls with lithium-ion batteries and lead-acid batteries.

Whether you are interested in zero-emissions, reduced engine maintenance or increased operator safety, idle reduction technology is a valuable system feature to add to your emergency response vehicles. It is available as an option on new apparatus and as an aftermarket solution.

Learn more with this helpful blog: 4 Operational Factors for Fire Truck Idle Reduction Technology

Electric Fire Truck

Pierce’s Volterra™ platform of electric vehicles offers a zero-emission vehicle that does not compromise on apparatus features, performance, functionality or safety. Pierce Volterra™ electric vehicles operate under electric power in all normal operational situations but can leverage an internal combustion engine for backup power in extended emergency operations.

Learn more about electric vehicle charging infrastructure now.

Types of Chassis

What is a chassis?

A chassis is the foundation on which a vehicle is built. The chassis consists of a frame and most of the vehicle components such as the engine, transmission, steering system, axle assemblies, wheels and brakes.

The chassis consists of a frame and most of the vehicle components such as the engine, transmission, steering system, axle assemblies, wheels and brakes.

How a fire truck chassis is designed affects its power and payload capabilities as well as the vehicle’s ability to function well in certain situations.

Pierce Manufacturing offers several custom and commercial chassis options.

| Arrow XT Chassis | The Pierce Arrow XT™ chassis is a heavy-duty workhorse built to deliver rugged, reliable service for both urban and rural high volume fire departments. A narrow design with 15o approach and departure angles and a 45o cramp angle provides exceptional maneuverability. Engines available up to 600hp and heavy-duty construction with oversized steel frame rails provide superior performance and handling. Yet, the Arrow XT is also designed for simplified serviceability. |

| Enforcer Chassis | The Pierce Enforcer™ chassis ensures reliable performance with powerful engine options, TAK-4® independent suspension and Pierce’s proprietary Command ZoneTM multiplexed electrical system. The Enforcer assures superior maneuverability in tight or difficult circumstances, and the large, wrap-around windshield offers maximum visibility. The Enforcer assures superior maneuverability in tight or difficult circumstances, and the large, wrap-around windshield offers maximum visibility. |

| Impel Chassis | The Pierce Impel® draws from the Velocity® chassis and a wealth of standard features and available options to give customers solid value and fire apparatus specifically outfitted to match local needs. From the wide, roomy cab that carries up to 10 personnel, to the large windshield and daylight windows that provide excellent visibility, to the ergonomic and safety details, the Impel performs to firefighter standards. |

| Saber Chassis | The Saber® is a classic fire truck chassis, Pierce’s proven industry standard, updated to meet the challenges of today’s firefighting. The Saber delivers all-around value, with features that include greater maneuverability, wrap-around visibility, more room for crew members, especially up front, easy-access maintenance and lower steps that make entrance and exit easier and safer. |

| Quantum Chassis | The Pierce Quantum® is designed to be bigger, more technologically advanced and boldly styled. The Quantum features a spacious, open cab with wrap-around dash, unparalleled panoramic visibility and comfortable transport for up to 10 personnel. The Quantum offers exceptional handling and maneuverability, easy-access service points and automatic stair steps that provide a safe forward entry and exit from the cab. |

| Velocity Chassis | Designed with input from real-life firefighters, the Pierce Velocity® is the essence of functionality, allowing personnel to prepare and perform efficiently. The wide, spacious cab has ample headroom, legroom and floor space to carry up to 10 people comfortably. Also, it can be configured for additional storage or equipment space. Massive steel frame rails ensure superior handling, the panoramic windshield provides maximum visibility, and wide doors make it easy for geared-up personnel to exit quickly and safely. |

Choosing the Right Engine

Selecting the right engine for a new apparatus is typically based on the geographic terrain and the power requirements of the fire truck.

- Geographic terrain. If your service area includes hills or mountains, an engine with higher horsepower is likely required. Conversely, if your community is flat with no hills, a smaller engine with lower horsepower will likely cover all of your needs.

- Power requirements. A heavy-duty fire truck loaded with equipment or a pumper truck with a large tank often require a more powerful, big block engine. An engine with higher horsepower is required for trucks with higher vehicle weight.

Pierce is proud to carry several engine brands to help each fire department find the right fit for its truck and the community. This includes the PACCAR MX-13 engine, built by PACCAR at its Columbus, Mississippi facility. In 2021, PACCAR granted Pierce exclusive use of the MX-13 engine in the fire truck industry. Learn more about PACCAR’s industry-leading design features now.

Learn more about PACCAR’s industry-leading design features now.

Choosing the Right Cab and Cab Doors

As a fire department works through the various stages of designing a fire truck, the mission of the vehicle remains at the core of every decision.

This holds true in the discussion of choosing the right cab and cab doors for a new apparatus. The cab choice aligns with the chassis of choice and thus, affects many of the configuration options available.

As your fire department thinks about the cab, there are a few questions to consider:

- What best meets your requirements regarding width, length and height?

- How many personnel will travel on board?

- Does the cab require a temperature-controlled area for pharmaceuticals or other sensitive materials?

- Are you planning to integrate any clean cab initiatives?

Pierce is proud to offer a variety of fire truck cab length, width and height options depending on the model selected, including cab lengths from 57-84 inches, roof styles that include flat or raised, at 10, 16, 20 or 24 inches, and cab widths that can be anywhere from 94 ¾ inches to 100 inches wide. Working with your fire truck manufacturer to understand the needs of your department and the mission of your truck can help determine the right cab choice.

Working with your fire truck manufacturer to understand the needs of your department and the mission of your truck can help determine the right cab choice.

In terms of cab doors, there are two considerations:

- Full height cab doors go all the way down and cover the door stepwell area.

- Barrier doors are designed to be shorter and clear a higher pathway, allowing them to open more easily over highway guardrails and parked cars.

Choosing the right cab door depends on the response area the fire department serves, and the types of obstacles firefighters might encounter on scene. If narrow streets, parked cars or roadway barriers are a concern, barrier doors offer prompt accessibility without fear of damage to the fire truck or nearby property.

Electrical System Selection

Every modern firefighting apparatus contains elements of electrical systems.

- Hardwired systems are constructed with fuses and relays.

This design allows trained fire department personnel to replace fuses and relays on their own. However, with these systems it is often difficult to diagnose issues.

This design allows trained fire department personnel to replace fuses and relays on their own. However, with these systems it is often difficult to diagnose issues. - Multiplex systems use computers and modules to manage inputs and outputs. The programs are simple to run but require training. The ability to diagnose issues and make modifications is fast and efficient.

Utilizing military-grade hardware and wire harnesses, Pierce’s electrical systems provide fire departments with technology built from the ground up with the desired level of interface, diagnostics, prognostics, maintenance, navigation and more.

The CZ Connect™ web-portal allows users to view, track, diagnose and troubleshoot the system. This expedites service support, allowing firefighters to intervene when critical failures occur to prevent further damage, improving budget forecasting and maintenance planning.

Learn more about Pierce electrical systems now.

Firefighters and the communities they serve rely on safe and dependable fire trucks. Fire truck safety systems are a critical component in fire truck design and manufacturing to protect the well-being of those tasked with saving lives.

Fire truck safety systems are a critical component in fire truck design and manufacturing to protect the well-being of those tasked with saving lives.

A fire truck chassis can be manufactured to include many safety systems, including:

- Side roll protection system for occupant protection

- Frontal air bags for occupant protection

- Seat belt warning system ensures occupants are properly buckled and ready reach seat belts to make buckling up one-handed and hassle-free

- Collision avoidance system warns before accidents can occur

- Lateral g-roll indicator alerts driver to excessive chassis roll

- Interior dome lights to enhance nighttime visibility

- Noise insulation and soundproofing provide a quieter interior environment

- Tinted windows reduce solar load

- Electronic Stability Control (ESC) and Roll Stability Control (RSC) auto braking systems

- Tire protection system including tire monitoring and tire blowout band protection

Additionally, fire trucks must be tested against NFPA standards to ensure compliance. Underwriter’s Laboratory (UL) completes all Pierce fire truck testing and ensures that each design detail is safe and effective for operators.

Underwriter’s Laboratory (UL) completes all Pierce fire truck testing and ensures that each design detail is safe and effective for operators.

Following industry standards and regulatory body requirements, fire truck crashworthiness is also tested by fire truck manufacturers. Fire truck cab crash testing is a process where fire apparatus are put through various tests, many of which are destructive in nature, to ensure the vehicle meets or exceeds industry standards. Learn more about the process and regulatory ratings and standards now.

Cab integrity is another key aspect to fire truck safety. The Society of Automotive Engineers outlines very specific cab integrity evaluation and safety requirements intended to protect the occupants of the cab. Learn more about these specifications and the different approaches fire truck manufacturers use to pass this standard in this informative blog: Fire Truck Cab Safety: Maintaining Cab Mounts In A Collision Test

Firefighting Foam System Selection

Firefighting foam systems are designed to improve the fire-extinguishing capabilities of water. Foam acts as a blanketing and cooling agent, and it can be produced by adding a foam concentrate to water on the fire truck.

Foam acts as a blanketing and cooling agent, and it can be produced by adding a foam concentrate to water on the fire truck.

A foam system allows a predetermined amount of foam to be mixed with water through the fire apparatus pump mechanisms. As such, anytime water is used, a foam system can be activated to improve water’s firefighting effectiveness.

There are two types of foam fire departments can select based on the types of calls they face.

- Class ‘A’ foam is used for Class ‘A’ fires, which include solid combustibles such as paper, wood, cloth and some plastics.

- Class ‘B’ foam is used for Class ‘B’ fires, which are fires that involve flammable liquids such as alcohol, ether, oil, gasoline or grease.

Much like any component, part or feature of custom apparatus, determining the right foam system requires a thorough understanding of a fire department's needs, including the following elements.

- How does your fire department intend to use a foam system?

- Determining the use of Class ‘A’ foam, Class ‘B’ foam and the appropriate percentage requirements for each run.

- What is the worst-case scenario?

- Compartment and storage space available.

- How much foam will your fire department use in “X” amount of time?

At Pierce, we collaborate with each department to decide which foam system best fits the apparatus during a typical emergency response. By offering and installing Hercules™ CAFS, Husky 3™, Husky™12 and Husky™ Industrial, Pierce ensures every fire department is equipped and satisfied with the foam system of their choice.

Learn more about foam system options in this helpful blog: Fire-Fighting Foam: What It Is and Why Fire Departments Need It

Choosing the Right Suspension

Choosing the right fire truck suspension system requires an understanding of your vehicle's role in the fleet as well as the needs of your fire department and service area. How the fire truck is used, how often it's used, and the environment in which it's used are all important factors to consider.

Other factors to consider include:

- The terrain in the service area

- Equipment that will be on board the apparatus

- Road layout and physical structures in the area

- The primary mission of the truck

The type of fire truck is also important. For example, a tanker truck will have different suspension system needs than a pumper, aerial, or rescue fire truck.

For example, a tanker truck will have different suspension system needs than a pumper, aerial, or rescue fire truck.

Below are some of the most common suspension systems in fire trucks:

- Multi or stacked leaf spring

- Parabolic leaf spring

- Walking beam or bogie

- Air ride

- Independent suspension

An independent suspension system allows each wheel on the same axle to move vertically and independently of the other. This type of suspension offers the best quality ride without sacrificing the lateral roll stiffness, making it easier to maneuver around tight corners. Other benefits include greater load-carrying capacity and better traction.

Pierce is proud to offer two independent suspension systems: TAK-4® Independent Front Suspension (IFS) and TAK-4® Independent Rear Suspension (IRS). These patented systems increase ride quality by up to 340-percent, reducing stress on the tires and overall vehicle components.

Other key features and benefits of Pierce’s independent suspension systems include:

- Less wear and tear on equipment

- Reduced maintenance

- Faster braking times

- Higher range of steering and wheel control

- Increased tire life

If a fire department needs extreme mobility, Pierce’s TAK-4 T3™ system combines the benefits of the TAK-4 IRS with a 100-percent mechanical rear steering system. The TAK-4 T3 system allows increased turning radius, increased tire life, and lane-to-lane turning.

The TAK-4 T3 system allows increased turning radius, increased tire life, and lane-to-lane turning.

Learn more about fire truck suspension systems here: Fire Truck Suspension Comparison Guide

Body Compartmentation

A fire department must work closely with its fire truck manufacturer early in the design process to discuss the function and primary use of the apparatus.

Why? To optimize equipment storage.

The type of equipment and tools, the mission of the truck, the number of firefighters on board and the type of firefighting gear required are all important elements to consider when customizing storage compartments.

Common compartment storage options include:

- Bumper storage

- Body compartment storage

- Mounting brackets

- Pull-out trays

- Tool storage boards

- Hatch compartments

Every fire truck is unique, and Pierce will work with you to help determine which compartment options are right for your fire department’s needs and how to find the right strategic storage configuration to support fast and efficient on-scene response.

Learn more about strategic compartmentation and how to integrate it in your fire truck design here: Fire Truck Storage: Compartment and Storage Systems FAQ

Pierce BMP Program

Now that you've had the opportunity to walk through many of the best design practices for building a fire truck, it’s time to put your plan into action.

Using Pierce's patented Build My Pierce™ (BMP™) program, an interactive custom configurator allows a choice of custom, market-trending options with a wide range of chassis and configurations available.

The BMP configurator does not sacrifice features to improve turnaround time but instead includes more than 1,500 available options and 35 customizable configurations. Pierce has delivered over 425 BMP vehicles to fire stations worldwide. The benefits include:

- Unprecedented 180-day delivery, depending on slot availability.

- Finalize details in the beginning, including a Pierce visit 21 days after booking.

- Completely custom-built and designed Pierce apparatus.

BMP is an excellent option if you are looking for an efficient ordering process and accelerated delivery for apparatus with a higher level of customization options in comparison to stock vehicles.

In ten minutes or less, your fire department can get a fully-engineered, custom truck drawing.

What are you waiting for?

American Fire Engines: 20+ Brands Reviewed

The Special Fire Engines of the United States of America are a national pride. The vast majority of fire engines are models created by private manufacturing companies exclusively to order. The main feature of such vehicles is that their main or base are civilian vehicles, which are modified by manufacturers specifically to fight fire. The most famous companies that produce special fire equipment in the USA are: Mack, Brockway, Autocar, GVC, Peterbilt, Kenworth, etc.

Classification of fire trucks in the US

Special fire trucks in the US can be divided into two main categories: Classic and Custom.

- Classic . This group includes trucks that have been specially modified and converted to extinguish fires. An example of these vehicles are the Peterbult 330-370 and International 4000-7000 trucks. The machines from the Classic group have a double cab and equipped with an extended chassis.

- Custom . This class consists of cabover vehicles. These cars have a cabin that resembles a wagon and can accommodate 6 to 12 people. For this class, the basic chassis of trucks is also used, but the engine, axles and gearboxes are most often made to order from third-party manufacturers.

An interesting difference between all American cars is their coloring. In the United States, the color of special fire engines is not regulated by the state of the country or even by the state authorities, but by the district. This explains why in different states, fire trucks and cars are painted in different colors: red, yellow, green, blue and black.

American fire trucks use modern engines that comply with the latest EPA-2010 standards, ESP, ABS, modern electronic tires and other auxiliary elements are also used. The following are the most famous and significant manufacturers of fire engines in the United States of America.

Mack

Mack is one of the oldest and most famous truck manufacturers in the USA. For a long period of time, Mack has been known for its own developments in the fire engine industry. The first model of a complete extinguishing vehicle was released by Mack at 1911 year.

A significant push in the development and distribution of automobiles occurred 45 years later, in 1956, when Mack bought the rights to the C-85. This cabover became the basis for the subsequent legendary C-95 and CF-600. The latter vehicle was considered the most popular fire truck of its time.

(Mack C-85 Fire Truck (1950 - 1989))

The most recent series of fire fighting vehicles, the MS, was produced in the 1990s. The fire chassis was made by Renault, which at the time owned Mack.

The fire chassis was made by Renault, which at the time owned Mack.

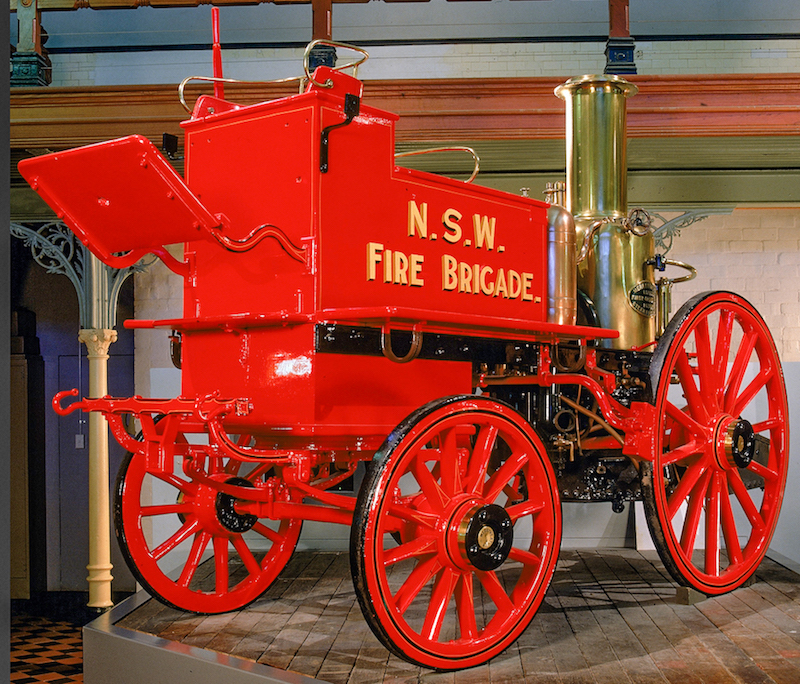

Ahrens-Fox - HME

Initially, this company was called Ahrens Manufacturing and began producing fire equipment in the 19th century. In 1887, a machine was produced based on a steam boiler, a few years later, in 1902, a machine was produced in which its own gasoline fire pump was installed to pump water.

Due to financial difficulties, in 1956 Ahrens-Fox was acquired by another well-known manufacturer of fire equipment - Mack. At the same time, in 2002, the manufacturer HME received the right to produce fire trucks on behalf of Ahrens-Fox Fire Engine.

Spectr 1871 base was now the basis for fire trucks, which was completed with different equipment.

(HME Spectr 1871 Fire Truck)

These American fire trucks are distinguished by unusual maneuverability and increased steering angle up to 52 degrees. Engines, including gas engines, are supplied by Cummins.

The company has its own complete trucks: RAT (Rapid Attack Truck), CAT (City Attack Truck), SilverFox. It was this company that produced the largest 4-axle fire truck, which is equipped with a 12-seat cab and a 500 hp engine.

It was this company that produced the largest 4-axle fire truck, which is equipped with a 12-seat cab and a 500 hp engine.

(HME RAT complete fire truck)

Emergency One

Emergency One or E-One is the youngest company in the fire industry, but already now it is called quite reputable. Now Emergency One is number two in the US and produces 700 fire trucks every year. The company was founded in 1974.

From the very beginning, the company presented itself as a manufacturer of various special fire fighting equipment. The company produces basic fire trucks on different types of chassis: jeeps, commercial vans and heavy trucks. In addition, cabover cars are produced by the manufacturer.

It should be noted that Emergency One produces complete machines with a lower center of gravity. The manufacturer uses Detroit Diesel engines, whose power is up to 500 horsepower, as well as Allison automatic transmissions.

The company successfully produced cars with autopumps, which belonged to the middle and heavy classes with a capacity of 4200 l / min and 7500 l / min, respectively.

It is in Emergency One that aluminum is actively used for the production of cabins and other body elements.

Two new types of chassis are popular today: Typhoon and Quest. Ferrara Fire Apparatus (FFA) It was founded by Chris Ferrar, who is a big and successful businessman and volunteer firefighter.

In 1998, cars appeared with their own chassis and cab, which was distinguished by an increased glass area. The line of cars was called Inferno. Then Igniter cars began to appear, as well as all-wheel drive 4x4 Inundator.

The following models are currently in production: Intruder 2, Ember, heavy Inferno XD, Igniter XD, Ultra and all-wheel drive Inundator. Interestingly, the manufacturer offers more than 50 different interior trim options for these cars.

(FFA Car Chassis - Ember)

(FFA Car Chassis - Inferno)

(FFA Car Chassis - Igniter)

Pierce

Currently, this company is a leader in the production of special fire equipment. Not so long ago, Pierce turned 100 years old.

Not so long ago, Pierce turned 100 years old.

In 1979, the manufacturer produced the first fire truck based on its own chassis. The car was called Pierce. After the release of the car, the stage of active implementation of new systems and innovative solutions began.

Pierce has an active export program that has sent about 250 vehicles to Ghana and China.

Today, Pierce is known for its diverse range of fire engines: Saber II, Arrow XT, Impel, Quantum II, Velocity and Dash CF, Suburban, Contender and Responder, and Oshkosh TFTT.

(Pierce Arrow XT Car Chassis)

(Pierce Velocity Car Chassis)

Rosenbauer America own developments in the US fire industry.

The history of the company began with an airport fire truck, then the Viper was released.

Over the years, Rosenbauer America has represented the following models in the US: General, Raptor, Centurion.

A few years ago, there was a new base for the complete Commander fire truck, equipped with an extended cab for 12 people, a 500 hp engine and an Allison 4000 EVS automatic transmission.

Another fresh addition is the T-Rex. The manufacturer unveiled a 32-meter platform lift. The machine is distinguished by the electronic SMART Aerial Controls System, which controls the safety of firefighters on a mission. The platform can support up to 570 kg of weight.

After some time, a similar vehicle appeared, lifting firefighters to a height of 34 meters.

(Car chassis Rosenbauer America - T-Rex)

Seagrave Fire Apparatus

Another not the youngest American company - Seagrave Fire Apparatus appeared in 1881. Initially, she produced ordinary stairs, which quickly became popular. Later, trailers with fire equipment, telescopic high-rise ladders, fire superstructures, pumps, and finally all-wheel drive vehicles began to be produced.

For large and populated cities, special turning and maneuvering vehicles were produced. Later, a whole series of Marauder cars was released, which are bought by the authorities of large American cities.

Today, Seagrave Fire Apparatus is one of the leaders in the production of fire trucks on its own chassis.

(SFA - Force Car Chassis)

Spartan/Crimson

Spartan/Crimson is a rather young major manufacturer of fire fighting equipment in the USA. The company appeared after the bankruptcy of the manufacturer of large trucks.

Snoozle industrial fire engines have been manufactured since the beginning. Later models of complete cars were released.

In 2003, Spartan created another "daughter" - Crimson, which manufactures and sells fire trucks from the Classic, Legend and Star series. The subsidiary also produces retractable ladders and lifts.

And Spartan is now producing full-scale chassis, which are very much in demand among other manufacturers. In addition to the "bare" chassis, the company is ready to offer models with installed cabs.

(Fire truck 125`Spartan Rear Mount ladder)

Sutphen

For a long time, Sutphen has been producing vehicles based on Intarnational. Later in 1967, the first car ladders were produced on their own chassis.

Later in 1967, the first car ladders were produced on their own chassis.

For a long time, the company has been a leader in experimentation and the first to develop unique innovations.

Developments include commercial chassis, complete tanks, autopumps, Shield and Guardian ladders.

At the top of Sutphen's merits and vehicles are the Sutphen Monarch Heavy Series Fire Trucks.

(Sutphen SP95 Fire Truck)

Alexis

Alexis is a typical family business that started in 1947. Production of fire equipment began in Illinois. The very first development was the American La France tank car.

Until now, in the vast majority of cases, Alexis is doing the rework. The manufacturer offers commercial chassis and complete vehicles. It is known that Belgian plastic is used in Alexis for its own cars.

(Alexis AFE Demo fire truck)

Crown

In 1904, the Crown company appeared in California, which manufactured buses. Between 1951 and 1985, 1,000 complete Firecoachs were produced by Crown, complete with their own chassis and cabs.

Between 1951 and 1985, 1,000 complete Firecoachs were produced by Crown, complete with their own chassis and cabs.

Cars were made from a special steel grade, which had increased corrosion resistance. This is what allows some cars to continue to be in service.

Duplex

Duplex has over 110 years of experience in the production of 4x4 fire trucks. Recently, production has shifted to chassis manufacturing, as competition has increased in the field of all-wheel drive vehicles. Thanks to this, it was possible to establish profitable cooperation with other manufacturers who used the Duplex chassis in their machines.

In 1966, a round cabover cab was created for a fire fighting team. Since 1986, the company has been called Simon-Duplex.

FMC

This company was founded in 1883 and then called John Bean. The popularity of the company quickly increased due to the release of branded fire pumps, which were widely used in the production of fire engines by other companies.

After merging with other firms in 1928, the company became known as FMC or Food Machinery Corporation. She used her own developments to create lifting mechanisms.

Success came only in 1984, when a budget series of cars was released, which was popular in small towns. Unfortunately at 1990, FMC went bankrupt.

Grumman

Grumman was founded in 1929 by engineer Leroy Grumman. The company is known as a manufacturer of various aircraft and all kinds of instruments for the exploration of the moon. In addition, the Grumman company produced all kinds of buses and vans, which were actively used by the US Postal Service.

In addition, Grumman is a manufacturer of fire trucks: Wildcat, Firecat, Attackcat, Aerialcat. In each of the models, winged metal is used, thanks to which cars are stably involved in our time. From 1992 years old, the production of fire equipment was bought out by another well-known company - KME.

American La France

American La France is another equally old and once sought-after brand that has been in operation since 1873, and since 1907 has been producing its own fire trucks. In 1938, the company released a 4-knee ladder that lifted firefighters and equipment to a height of up to 33 meters. Already in 1939, it produced the first fire extinguishing vehicle, in which the cab was located above the engine. Interestingly, it is American La France that is a conservative manufacturer, which until 1935 years kept the chain drive.

In 1938, the company released a 4-knee ladder that lifted firefighters and equipment to a height of up to 33 meters. Already in 1939, it produced the first fire extinguishing vehicle, in which the cab was located above the engine. Interestingly, it is American La France that is a conservative manufacturer, which until 1935 years kept the chain drive.

In the 1960s, updated models of fire engines appeared, one of which was first called the "700", and then the Century.

In 1995, the new Eagle series came out, equipped with its own chassis and aluminum cab with a length of 2.4 and 3.7 meters. This modern series of fire trucks was a prominent representative of the classic series.

Later Metropolitan, Freightliner M2 and Liberty cars appeared.

KME (Kovach Mobile Equipment)

V 1946 Kovach Mobile Equipment or KME was formed. Initially, it was a simple workshop for repairing cars, but already in 1970 the first fire units were produced.

Today, Kovach Mobile Equipment is the main supplier of fire trucks to the US Army. The most famous model is the P-18, which was created specifically for use on military airfields. Based on International Paystar (6×6) chassis.

The most famous model is the P-18, which was created specifically for use on military airfields. Based on International Paystar (6×6) chassis.

The company now manufactures and offers a variety of fire truck chassis: Panther, Predator III and Severe Service. For export to Latin America, the Motobomba tank truck has been developed.

The smallest are mini-tanks based on small jeeps, while the largest are Legacy and Eliminator trucks.

Hahn

Hahn was founded in Pennsylvania in 1923 and was once considered the largest fire fighting company in the United States. For base cars, personal cabs and chassis were used, which were also purchased by other, smaller manufacturers.

In the 1970s, a 350 hp GM V8 powered ladder appeared.

The company is now dormant since it went bankrupt in 1989, but some of the Hahn machines are still in service.

Maxim

Maxim was founded in 1914 by Maxim Carlton. Once upon a time, Maxim Motor was considered a rival for well-known and large manufacturers Ahrens Fox and American La France. Maxim was considered to produce better products on their bonneted chassis.

Maxim was considered to produce better products on their bonneted chassis.

The company has been able to maintain the popularity of bonnet models for 25 years.

Then the brand began to lose its initial momentum and by 1990 was closed due to bankruptcy. The most popular model, the 1977 Maxim, was a bonneted model and still serves in some US cities.

4Guys

4Guys is a fire fighting equipment company that quickly entered the market in 1974. The name of this company came from four co-owners who opened a company in Pennsylvania.

The manufacturer specializes in the creation of elliptical tanks. In addition, both standard cubic tanks and complete fire models on commercial chassis are being created.

Smeal

Smeal is distinguished by its stability and rapid development. The company was founded in 1955 and at that time it specialized in the repair of agricultural machinery. In 1963, they began to repair fire trucks. After some deliberation, the manufacturer created his own fire engine.

Today Smeal produces standard machines: Razor, Volunteer, Urban and Freedom, as well as unusual customer orders.

Based on commercial Spartan chassis.

Pirsch

Pirsch was founded by professional firefighter Peter Pirsch, who designed and manufactured sliding fire escapes himself.

The company started almost 120 years ago and since then, when it comes to ladders, Pirsch immediately pops up in the mind. Manufacturers from this company were the first in the country to use aluminum for the manufacture of stairs. In addition, they were the first to teach the use of a closed cabin in fire engines and the first to come up with a trailed hydraulic ladder.

The last fire truck was produced in 1987.

Ward La France

Ward La France is an example of the most famous of all the failed firms. Founded in 1916, the company was engaged in the production of a wide variety of commercial vehicles, vans, tractors and even trolleybuses. In 1931, the first fire truck was produced, and by the middle of that century, the company had created a large number of commercial chassis for various types of fire trucks.

P-80 Ambassador is one of the most famous models, which appeared in 1968. Unfortunately, the production was not cheap and therefore by 1979 the company went bankrupt and stopped producing fire engines.

Multifunctional fire truck - Fire fighting equipment - rescue equipment and tools, lighting equipment, as well as fire-technical equipment and a supply of fire extinguishing agents;

l/s

(l/min)

4. 0

0

(240)

MPa

(KGS/cm 2 )

10.0

(100.0)

l/s

(l/min)

1,38

(83.33)

1.16 Filling out water from an open water source, not more than

with

(minutes)

1. 17 Submersible pump parameters for water intake from a remote open water source

17 Submersible pump parameters for water intake from a remote open water source

1.17.1 Maximum head0325

M

27

1.17.2 The maximum feed is 10 m, at least

l/s

5,000

5,000

5,000

5,000

5,000

5,000,000 3 (300)

1.18 The minimum water pumping level from the shallow open water source, at least

mm

15

1.20.3 performance at water temperature 165 ° C, at least

l/s

(l/min)

2. 0

0

(120)

1.20.4 The pressure on the output pipe at a water temperature of 165 ° C, at least/not more than

MPa

(kgf/cm 2 )

3.0/4,0

(30/40)

1.20.5 Productivity at water temperature not more than 115 °C, not less than

l/s

(l/min)

4.0

(240)

1.20.6 POWERS on the output pipeline at a water pace of water, not more than 115 ° C. at least/no more than

MPa

(kgf/cm 2 )

1.6/4.0

(16/40)

1. 20.7 Production productivity at temperature at a temperature productivity at a temperature. water 300 ºС, not less than

20.7 Production productivity at temperature at a temperature productivity at a temperature. water 300 ºС, not less than

l/s

1.22.2 Earth level height, at least

m

7

.3 SUMPLE 9000 9000

2/(500+500)

1.22.4 Number of remote masts

pieces

2

pieces/W

2/(500+500)

1.22.6 Cables for connecting external consumers

pieces

2 Reliability indicators

2.